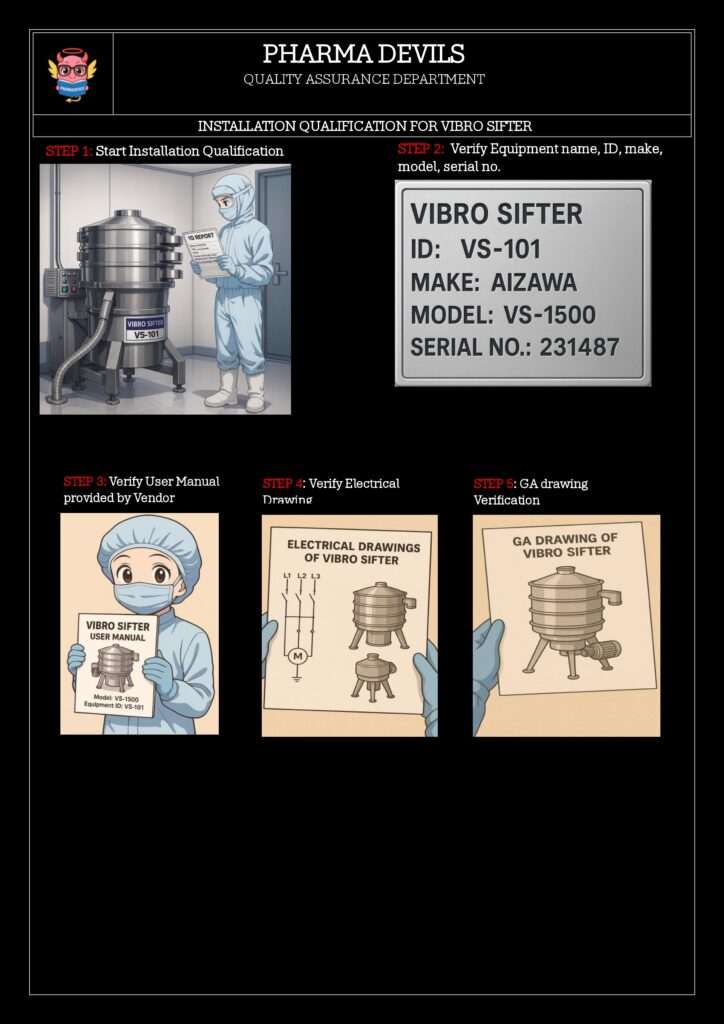

INSTALLATION QUALIFICATION (IQ)

48″ VIBRO SIFTER

Protocol & Report

1.0 GENERAL INFORMATION

Company Name: Pharmadevils Pvt. Ltd.

Site: Solid Oral Dosage Plant, Unit–I

Equipment Name: Vibro Sifter

Equipment ID / Tag No.: VSF-048-01

Equipment Description: 48-inch single-deck vibro sifter for sieving granules and powders

Make / Manufacturer: SwiftTech Process Equipment Pvt. Ltd.

Model: ST-VS-48-SD

Serial No.: STVS48/2025/017

Location / Room: Granulation Room–1, First Floor

Area Classification: Grade D (Non-sterile, controlled)

URS No.: ZP/ENG/URS/VSF/012

Purchase Order No.: ZP/PO/PRC/2025/104

IQ Protocol No.: ZP/VAL/IQ/VSF/048/01

IQ Report No.: ZP/VAL/IQ/VSF/048/01/R0

Date of Installation: 15-Nov-2025

2.0 OBJECTIVE

The objective of this Installation Qualification (IQ) is to verify and document that the 48″ Vibro Sifter (ID: VSF-048-01) has been received and installed as per approved specifications, drawings and manufacturer’s recommendations, and that all required utilities, materials of construction, safety and GMP requirements are in place prior to Operational Qualification (OQ).

3.0 SCOPE

This IQ covers:

- Physical receipt and installation of the 48″ vibro sifter

- Verification of location, utilities, materials of construction, safety and accessories

- Verification of availability of relevant documents and SOPs

It applies to VSF-048-01 installed in Granulation Room–1.

4.0 RESPONSIBILITIES

- Engineering: Installation, technical verification, and completion of IQ checks

- Production: Verification of suitability and support during checks

- Quality Assurance (QA): Review and approval of IQ protocol and report

- Validation: Coordination, documentation and conclusion

5.0 EQUIPMENT DETAILS

5.1 Basic Data

| Parameter | Details |

|---|---|

| Equipment Name | Vibro Sifter |

| Equipment ID | VSF-048-01 |

| Manufacturer | SwiftTech Process Equipment Pvt. Ltd. |

| Model | ST-VS-48-SD |

| Serial Number | STVS48/2025/017 |

| Type | 48″ Single-Deck Vibro Sifter |

| Application | Sieving of granules and powders |

| Location | Granulation Room–1, First Floor |

| Utility Required | Electrical Power (415 V, 3Φ, 50 Hz) |

5.2 Short Description

The 48″ vibro sifter is a single-deck vibrating sieving machine used to separate oversized and undersized particles from granules and powders. It consists of a sieve deck with mesh, top cover with clamps, vibratory motor, base frame with rubber mounts, and inlet/discharge chutes. Product-contact parts are SS 316L.

6.0 REFERENCE DOCUMENTS – SAMPLE-FILLED

| Sr. No. | Document | Document No. | Status / Remarks |

|---|---|---|---|

| 1 | User Requirement Specification (URS) | ZP/ENG/URS/VSF/012 | Available and approved. |

| 2 | Purchase Order (PO) | ZP/PO/PRC/2025/104 | Available. |

| 3 | Vendor GA / Assembly Drawing | ST-DRW/VSF48/GA/2025-01 | Latest revision received and filed. |

| 4 | Plant Layout Drawing (Granulation Area) | ZP/ENG/LYT/GRN/2023/07 | Shows VSF-048-01 at correct location. |

| 5 | Electrical Wiring Diagram | ST-DRW/VSF48/ELEC/2025-02 | Available and legible. |

| 6 | Operation & Maintenance Manual | ST/MAN/VSF48/OM/2025 | Received with machine. |

| 7 | MOC Certificates | ST/QC/MOC/VSF48/2025/017 | SS 316L confirmed for product-contact parts. |

| 8 | Motor Test / Nameplate Certificate | ST/QC/MOTOR/48VS/2025/017 | Available; matches nameplate. |

| 9 | Warranty Certificate | ST/WAR/VSF/2025/017 | Available. |

| 10 | Spare Parts List | ST/SPP/VSF48/2025 | Available. |

Result: All required reference documents are available and acceptable.

7.0 PRE-INSTALLATION VERIFICATION

7.1 Receipt and Condition Check

| Sr. No. | Checkpoint | Observation | Result (Complies / Does Not Comply / NA) | Remarks |

|---|---|---|---|---|

| 1 | Equipment received as per PO | Make, model and qty as per PO | Complies | Checked against PO. |

| 2 | Physical condition on receipt | No dents, deformation or missing major parts | Complies | Verified on 14-Nov-2025. |

| 3 | Nameplate details | Model ST-VS-48-SD, 415 V, 3Φ, 50 Hz, 2.2 kW | Complies | Matches URS. |

| 4 | Accessories (gaskets, clamps, etc.) | All items as per packing list | Complies | No shortage observed. |

| 5 | Sieve sets received | 20#, 40#, 60# meshes received (48″ dia.) | Complies | Marked and stored properly. |

Conclusion: Pre-installation checks Comply.

8.0 INSTALLATION VERIFICATION

8.1 Location and Layout

| Sr. No. | Checkpoint | Observation | Acceptance Criteria | Result |

|---|---|---|---|---|

| 1 | Location in plant | Installed in Granulation Room–1 | As per approved layout ZP/ENG/LYT/GRN/2023/07 | Complies |

| 2 | Orientation | Discharge aligned towards RMG discharge trolley | Orientation conforms to material flow design | Complies |

| 3 | Working space | > 1 m clearance on operating side and front | Adequate access for operation and maintenance | Complies |

| 4 | Impact on man/material movement | Aisles are free, no obstruction | Does not block normal or emergency routes | Complies |

8.2 Mechanical Installation

| Sr. No. | Checkpoint | Observation | Acceptance Criteria | Result |

|---|---|---|---|---|

| 1 | Base and levelness | Machine stable, checked with spirit level | No rocking; acceptable levelness as per engineering practice | Complies |

| 2 | Anchor bolts (if provided) | Four anchor bolts fixed and tightened | All bolts present and tight | Complies |

| 3 | Rubber mounts / springs | Four mounts intact, no cracks | All mounts present and undamaged | Complies |

| 4 | Sieve deck (48″) condition | No dents/warping; fits properly | Sieve deck undamaged and properly seated | Complies |

| 5 | Mesh condition (20#, 40#, 60#) | No torn wires, no corrosion | Mesh intact and visually acceptable | Complies |

| 6 | Top cover and clamps | Top cover sits flush, all 6 clamps functional | No gaps; secure clamping | Complies |

| 7 | Inlet / outlet alignment | Inlet aligned with RMG discharge; outlet to IPC | No visible leakage path; alignment as per process design | Complies |

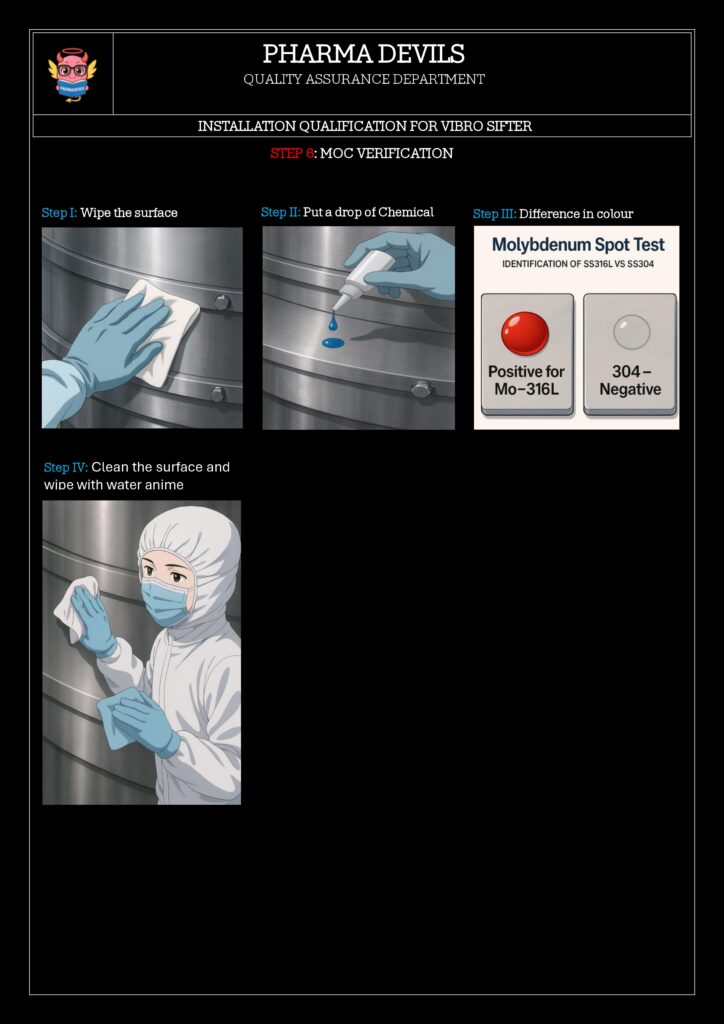

8.3 Material of Construction (MOC)

| Component | Expected MOC | Observation (Certificate / Visual) | Result | Remarks |

|---|---|---|---|---|

| Sieve deck (48″) | SS 316L | Certificate ST/QC/MOC/VSF48/2025/017; no rust | Complies | Internal surface smooth and cleanable. |

| Product-contact bowl / ring | SS 316L | Same certificate; visually acceptable | Complies | |

| Top cover (product-contact side) | SS 316L | Same certificate; no pitting or scratches | Complies | |

| Discharge chute | SS 316L | Certified and visually acceptable | Complies | |

| Gaskets / seals (product side) | Silicone (food-grade) | Vendor spec; transparent silicone, no cracks | Complies | Material: Food-grade silicone. |

| Frame / legs | SS 304 | Visual check; no corrosion or flaking | Complies | Outside product-contact area. |

Overall MOC Result: Complies with URS and vendor certificates.

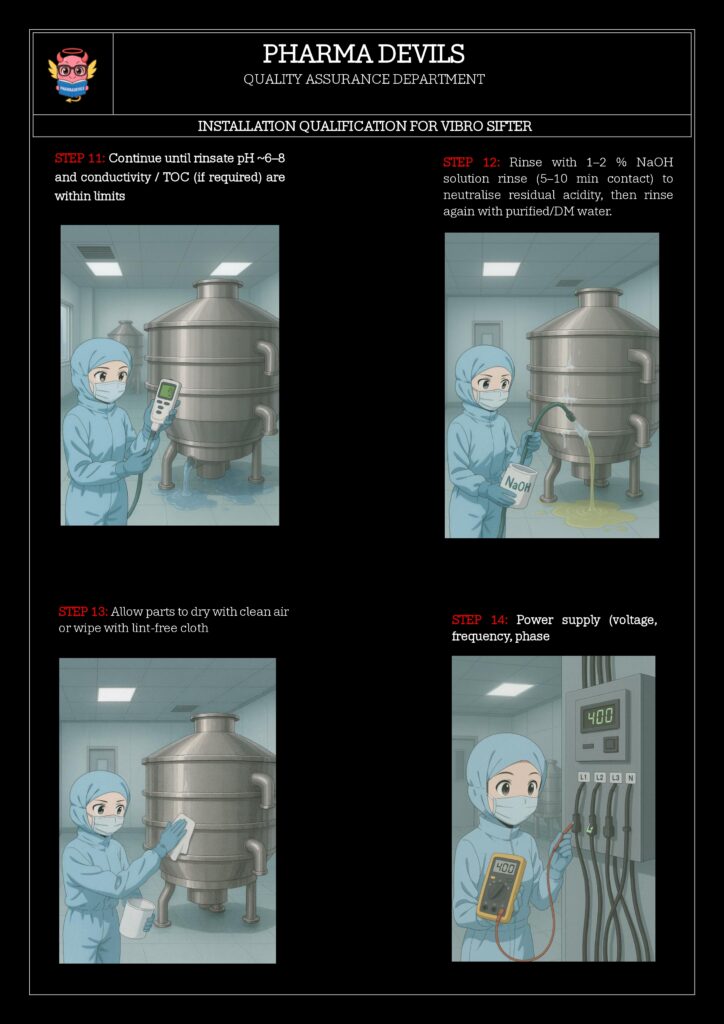

8.4 Electrical and Utilities

| Sr. No. | Checkpoint | Observation | Acceptance Criteria | Result |

|---|---|---|---|---|

| 1 | Power supply rating | 415 V, 3-phase, 50 Hz supply available at panel | Matches motor rating and URS | Complies |

| 2 | Motor rating & nameplate | 2.2 kW, 415 V, 3Φ, 50 Hz, 1440 RPM, IP55 | As per PO and vendor docs | Complies |

| 3 | Earthing | Separate earth connection provided to frame | Earth resistance as per site SOP (tested 1.1 Ω) | Complies |

| 4 | Cable size and termination | 4-core 2.5 sq.mm copper cable; properly terminated | Cable size adequate; terminations tight and labeled | Complies |

| 5 | MCB / overload protection | 10 A 3-pole MCB and overload relay set at 5 A | As per electrical design note | Complies |

| 6 | Local starter / control panel | Panel mounted on adjacent wall; labeled “Vibro Sifter” | Accessible, not obstructed, labels clear | Complies |

VFD: Not provided for this model (direct-on-line starter).

Result: NA for VFD-related checks.

8.5 Safety and GMP Checks

| Sr. No. | Checkpoint | Observation | Acceptance Criteria | Result |

|---|---|---|---|---|

| 1 | Guards on moving parts | All moving elements enclosed within housing | No exposed rotating parts in normal use | Complies |

| 2 | Sharp edges / burrs | No sharp edges felt on clamps, handles or frame | No risk of injury during normal handling | Complies |

| 3 | Equipment identification tag | SS tag “VSF-048-01” fixed on front side | Readable and permanent ID visible | Complies |

| 4 | Surface condition | No rust, no flaking paint, surfaces clean | Surfaces smooth and cleanable | Complies |

| 5 | Use of wood in clean area | No wooden parts in equipment or immediate vicinity | No wood in product-contact/clean zone | Complies |

| 6 | Access to emergency exits | Equipment does not block doors or fire equipment | Compliance with safety layout | Complies |

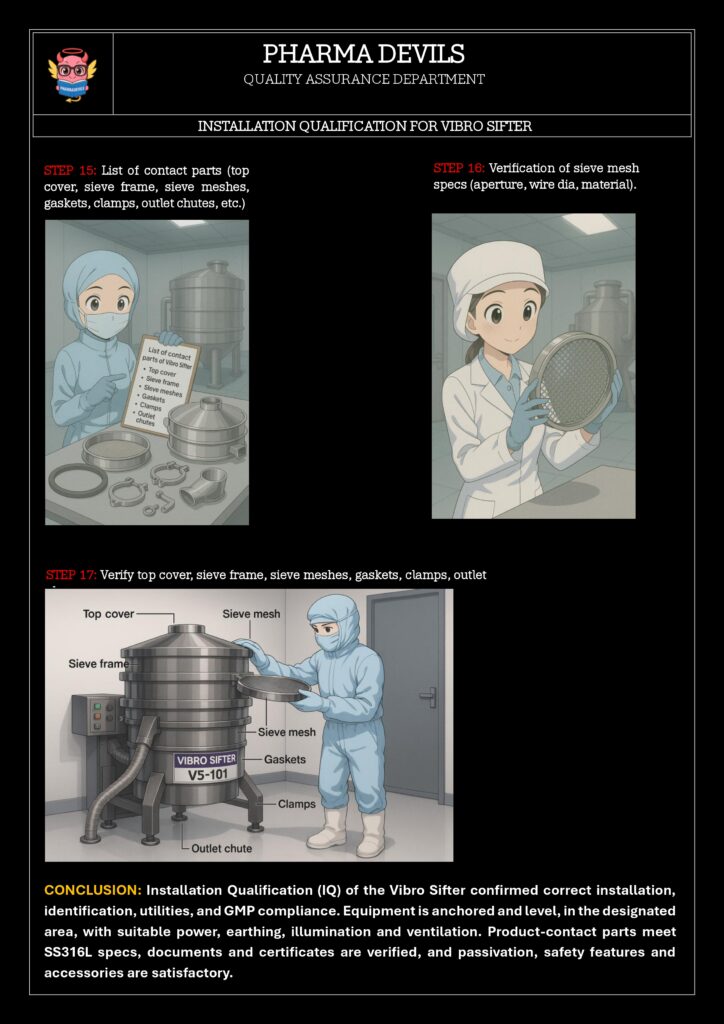

9.0 ACCESSORIES AND SIEVE DETAILS (FILLED)

| Sr. No. | Item | Specification / Details | Qty Received | Status / Remarks |

|---|---|---|---|---|

| 1 | Vibratory motor | 2.2 kW, 415 V, 3Φ, 50 Hz, IP55 | 1 | Installed and connected. |

| 2 | Sieve – 20# mesh, 48″ | SS 316L frame, labeled “20# – 48” | 1 | Stored in sieve cabinet. |

| 3 | Sieve – 40# mesh, 48″ | SS 316L frame, labeled “40# – 48” | 1 | Stored in sieve cabinet. |

| 4 | Sieve – 60# mesh, 48″ | SS 316L frame, labeled “60# – 48” | 1 | Stored in sieve cabinet. |

| 5 | Silicone gaskets | Food-grade, suitable for 48″ deck and cover | 2 sets | No cracks, stored in polybags. |

| 6 | Clamps for top cover | SS clamps with wing nuts | 6 | All functional. |

| 7 | Tools (spanner set) | For clamp and bolt tightening | 1 set | Kept in maintenance locker. |

10.0 SOP AND MAINTENANCE READINESS

| Sr. No. | Item | SOP / Doc No. | Status / Remarks |

|---|---|---|---|

| 1 | SOP for Operation of Vibro Sifter | ZP/PRD/SOP/GRN/045 | Approved; applicable to VSF-048-01. |

| 2 | SOP for Cleaning & Line Clearance | ZP/PRD/SOP/CLN/021 | Approved; includes cleaning of 48″ sieves. |

| 3 | SOP for Sieve Handling & Integrity Check | ZP/PRD/SOP/SIV/009 | Approved; sieve integrity testing defined. |

| 4 | Preventive Maintenance Schedule | ZP/ENG/PM/SCH/2025/GRN/VSF-01 | Equipment added to PM plan (quarterly maintenance). |

| 5 | Calibration / verification (if instruments) | ZP/QC/CAL/PANEL-METERS | Not applicable (no panel meters on this unit). |

11.0 DEVIATIONS DURING IQ

Summary:

No deviations were observed during the execution of this Installation Qualification.

| Sr. No. | Deviation Description | Impact (L/M/H) | CAPA / Action | Responsible | Target Date | Closure (Sign/Date) |

|---|---|---|---|---|---|---|

| 1 | Not applicable | – | – | – | – | – |

12.0 IQ ACCEPTANCE CRITERIA – VERIFICATION

- All required documents (URS, PO, drawings, manuals, certificates) are available and acceptable. ✔

- The 48″ vibro sifter is installed at the correct location as per approved layout. ✔

- Mechanical installation (mounting, levelness, sieves, covers, clamps, inlet/outlet) is satisfactory. ✔

- Materials of construction for product-contact parts are SS 316L (or as per URS) and confirmed by certificates and visual checks. ✔

- Electrical supply and earthing comply with URS and site standards; protective devices are correctly rated. ✔

- Safety and GMP features (guards, no sharp edges, proper labeling, no flaking surfaces or wood) are verified. ✔

- Required SOPs and PM plans are in place and approved. ✔

- No deviations remain open. ✔

Conclusion:

The IQ acceptance criteria for 48″ Vibro Sifter (VSF-048-01) have been fully met. The equipment is considered satisfactorily installed and is recommended for Operational Qualification (OQ).

13.0 APPROVAL

Performed By (Engineering / Validation)

Name: Mr. A. Kumar

Designation: Executive – Engineering

Signature: ___________________________

Date: 20-Nov-2025

Reviewed By (Production)

Name: Ms. R. Sharma

Designation: Manager – Production

Signature: ___________________________

Date: 21-Nov-2025

Reviewed By (Quality Assurance)

Name: Mr. S. Mehta

Designation: Executive – QA

Signature: ___________________________

Date: 21-Nov-2025

Approved By (Head – QA / Validation)

Name: Dr. V. Rao

Designation: Head – Quality Assurance

Signature: ___________________________

Date: 22-Nov-2025