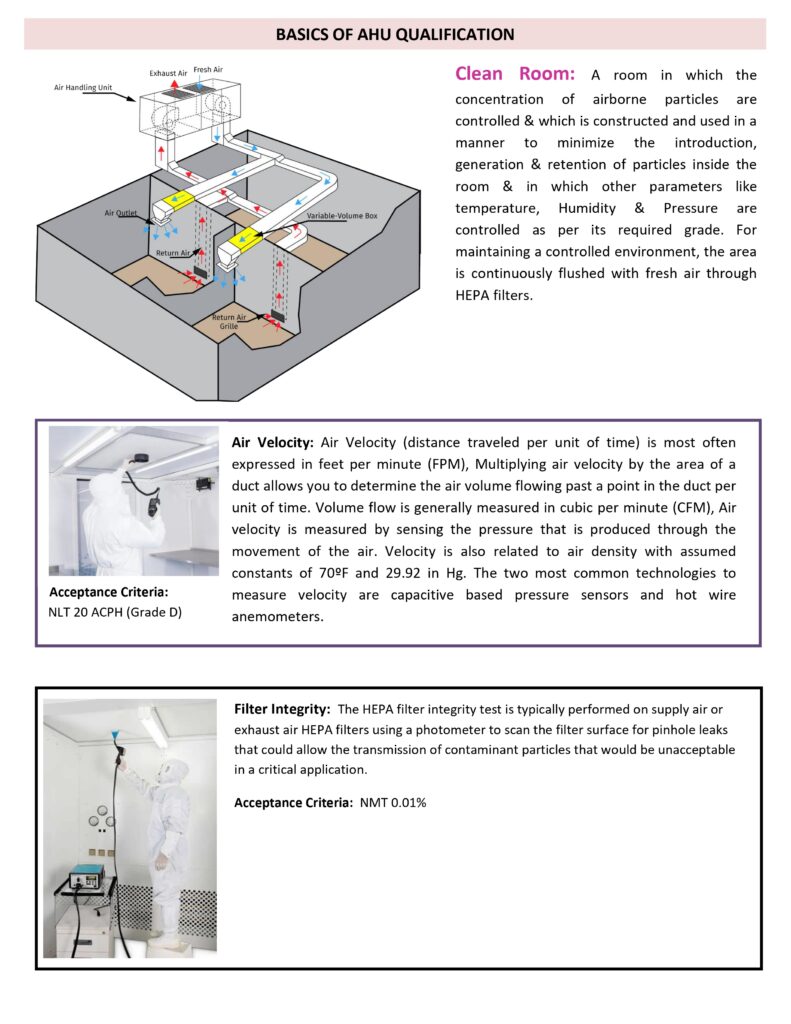

Air Handling Unit (AHU) qualification is a key GMP activity to ensure that HVAC systems consistently provide the required environmental conditions for the manufacturing of pharmaceutical products. AHUs control temperature, relative humidity, air cleanliness, pressure differentials and airflow patterns, all of which directly impact product quality, operator safety and microbial / particulate control in classified areas.

Qualification of an AHU typically follows the V-model: Design Qualification (DQ), Installation Qualification (IQ), Operational Qualification (OQ) and Performance Qualification (PQ). During DQ, user requirements and design specifications are reviewed to confirm that the AHU and associated HVAC system are suitable for the intended cleanroom classification and process needs. In IQ, the installed AHU is verified against approved drawings, datasheets and specifications, including filters (pre-filters, fine filters, HEPA filters), fans, dampers, coils, sensors and instrumentation.

OQ focuses on demonstrating that the AHU operates as designed within defined limits. Tests usually include air flow and air changes per hour, filter integrity (for HEPA filters), temperature and humidity control, alarm and interlock checks, and pressure differential verification between rooms of different classifications. Control logic and Building Management System (BMS) functions are also challenged.

PQ confirms that the AHU and HVAC system maintain the required conditions over time during routine operation. This includes long-term monitoring of temperature, humidity, pressure differentials, non-viable and viable particulate levels, and recovery tests after disturbances such as door openings or power interruptions.

Properly executed AHU qualification, supported by risk assessment and periodic requalification, provides documented evidence that the HVAC system is fit for purpose and capable of maintaining a controlled environment throughout the product lifecycle.