Batch release in pharma is the formal, documented decision that confirms a manufactured batch is fit for sale and patient use. It verifies that teams produced, tested, packed, stored, and reviewed the batch in compliance with approved procedures, GMP, and the marketing authorization/registered dossier. Quality Assurance (QA), operating independently from production, typically owns the batch release process and applies it as one of the most critical controls in the Pharmaceutical Quality System.

What batch release involves

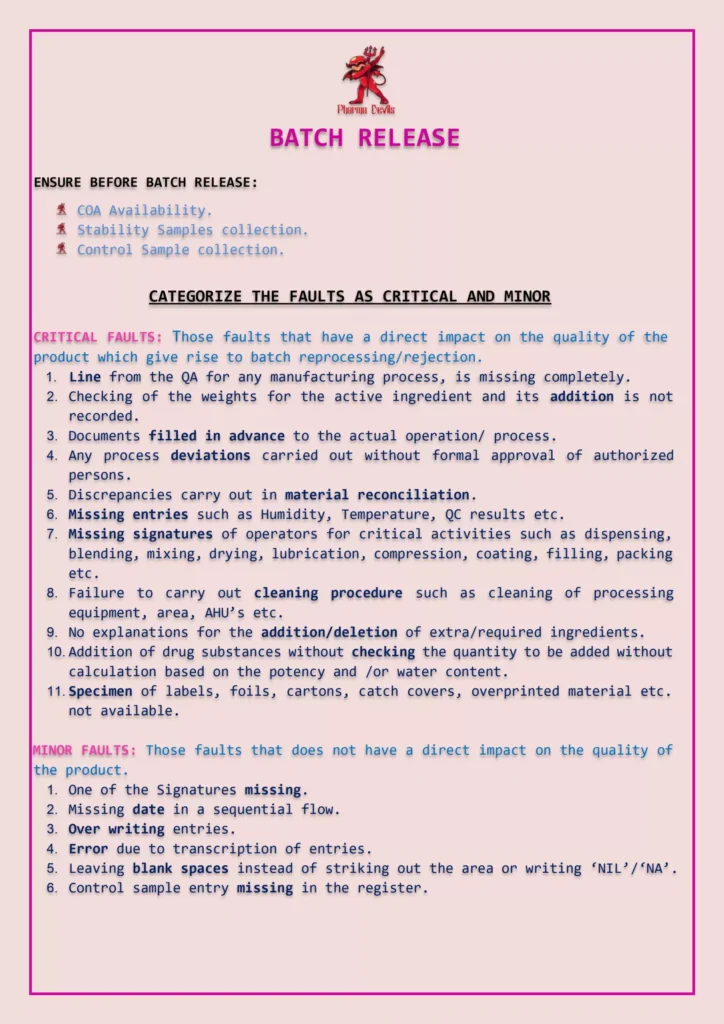

- Review of manufacturing and packaging records (BMR/BPR):

QA confirms all steps were performed as per the approved master documents, with complete entries, signatures, and traceable annexures (dispensing sheets, equipment logs, line clearance, in-process checks). Any deviations, alarms, or interventions must be documented and assessed. - QC testing and disposition:

QC confirms test results meet specifications (identity, assay, impurities, dissolution, microbial limits, sterility/endotoxin where applicable). QA checks that all laboratory data are complete, reviewed, and any OOS/OOT investigations are closed with justified conclusions. - Deviation, change control, and CAPA status:

QA verifies all deviations impacting the batch are investigated with root cause and CAPA. Open critical CAPAs or major changes without assessment can block release. - Environmental/utility and equipment status (where relevant):

For sterile/controlled products, QA reviews environmental monitoring, water/steam/air quality, sterilization records, filter integrity, and equipment calibration/maintenance status. - Labeling and packaging compliance:

Verification that correct artwork/version was used, coding is correct (batch/expiry), and packaging material reconciliation is acceptable. This prevents mix-ups and mislabeling. - Final decision and documentation:

QA (or an Authorized Person/QP in some systems) issues release authorization, signs the release certificate, and ensures batch traceability for distribution. If issues exist, the batch may be quarantined, reworked/reprocessed (if justified), or rejected.

Why it matters

Batch release is the last internal barrier protecting patients. Weak batch release leads to recalls, regulatory action, and patient harm. A robust release process is evidence-based, risk-assessed, and fully documented.