Calibration in pharma is the documented process of verifying and adjusting instruments so they measure accurately and consistently within defined limits. It is a fundamental GMP requirement because critical decisions—batch release, process control, environmental monitoring, and safety—depend on reliable measurements. Calibration supports the facility’s validated state and prevents errors caused by drift, wear, or environmental influences.

What gets calibrated

Typical GMP instruments include balances, weights, thermometers, RTDs, pressure gauges, differential pressure transmitters, flowmeters, pH meters, conductivity meters, TOC analyzers, autoclave sensors, data loggers, particle counters, timers, pipettes, HPLC/GC systems (critical modules), UV/FTIR, and cold-room/warehouse temperature sensors. Utilities and cleanroom devices (HVAC sensors, magnehelic gauges, BMS transmitters) are also included where they affect quality.

Calibration system elements

- Instrument master list and classification: Each instrument is identified with a unique ID and classified (critical/non-critical) based on impact to product quality. Critical instruments require tighter control, more frequent calibration, and stronger impact assessment if overdue or out of tolerance.

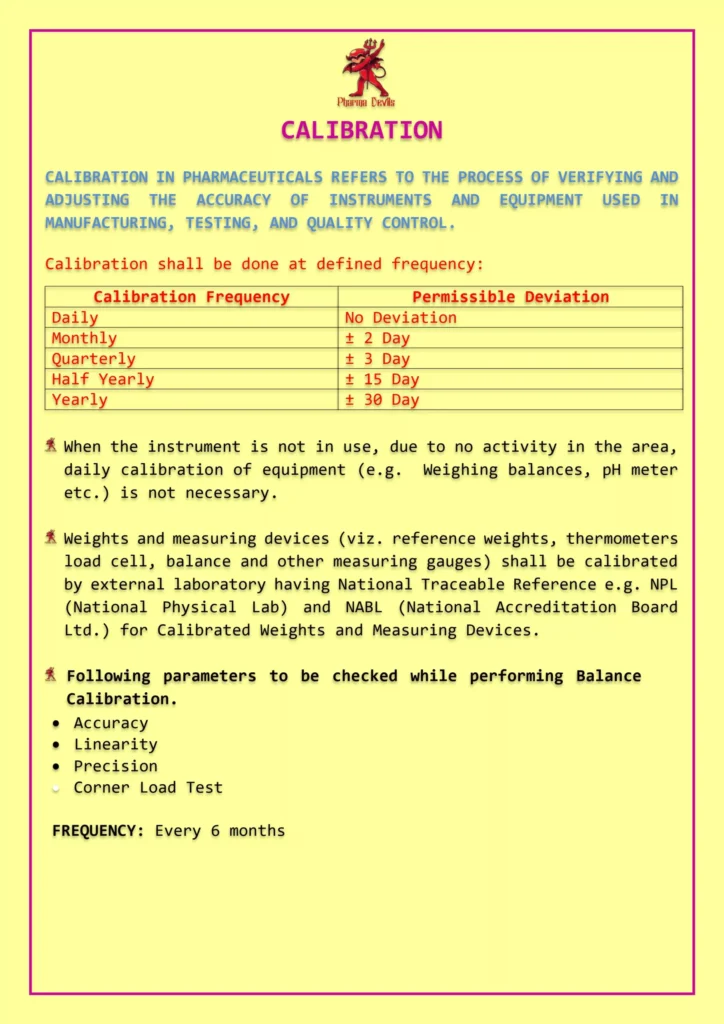

- Traceability to standards: Calibrations must use reference standards traceable to national/international standards (e.g., NABL/ISO/IEC 17025 accredited references where appropriate).

- Defined frequency and acceptance criteria: Frequencies are set by risk, manufacturer guidance, historical stability, and usage intensity. Acceptance limits are based on process needs and method requirements.

- Calibration procedure and records: SOPs specify method, points checked, environmental conditions, measurement uncertainty considerations, and required documentation. Records include “as found” and “as left” results, standards used, due date, technician, and reviewer.

Handling deviations and out-of-tolerance (OOT)

If an instrument is found out of calibration, pharma expects a documented investigation: impact on batches/tests since last acceptable calibration, review of associated data, and decisions on retesting or batch disposition. CAPA may include reduced intervals, repairs, training, or replacement.

GMP benefits and common findings

A good calibration system prevents measurement errors, supports data integrity, and improves audit readiness. Common inspection findings include overdue calibrations, missing traceability of standards, poor impact assessment for OOT instruments, and inconsistent instrument labeling (status tags).