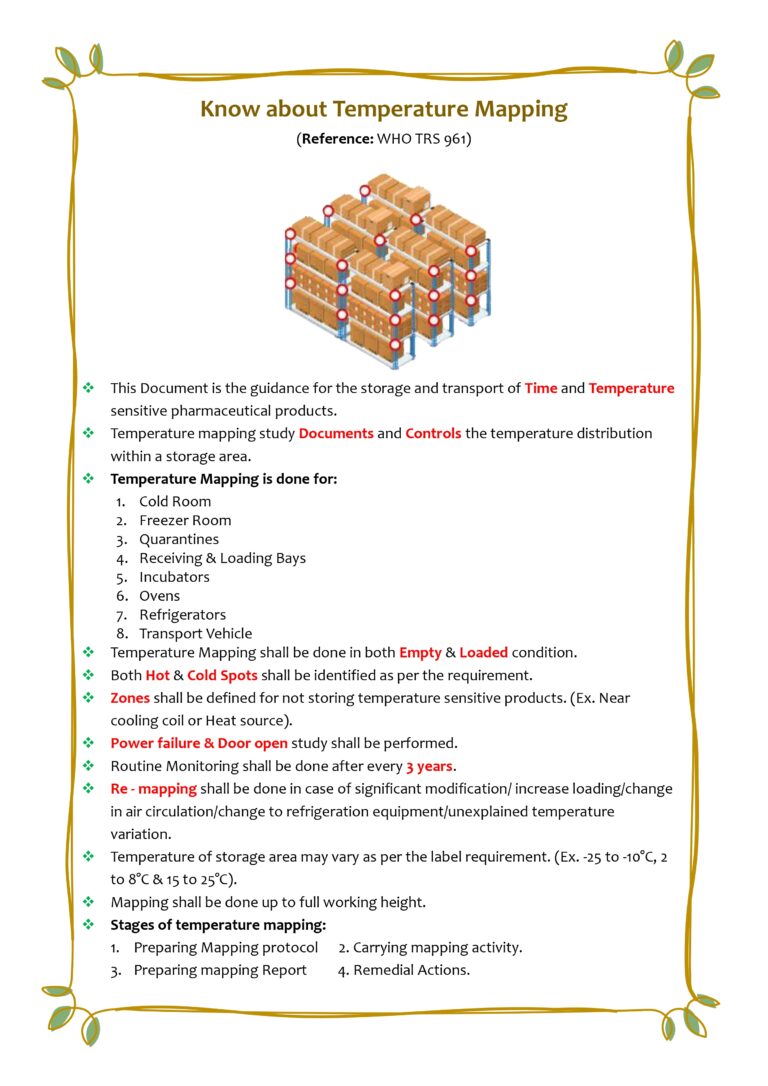

KNOW ABOUT TEMPERATURE MAPPING IN PHARMA

Temperature mapping in pharma is a documented study used to demonstrate that storage areas such as warehouses, cold rooms and stability chambers maintain uniform, controlled temperatures under normal operating conditions. It is a critical GMP requirement, as temperature excursions can…