Swab sampling is a direct surface-sampling technique used in cleaning validation to verify removal of product residues, cleaning agents, and potential contaminants from equipment after cleaning. It is especially valuable for “worst-case” locations where residues are most likely to remain, such as corners, gaskets, welds, dead legs, valves, spray-ball shadow areas, and hard-to-clean equipment parts.

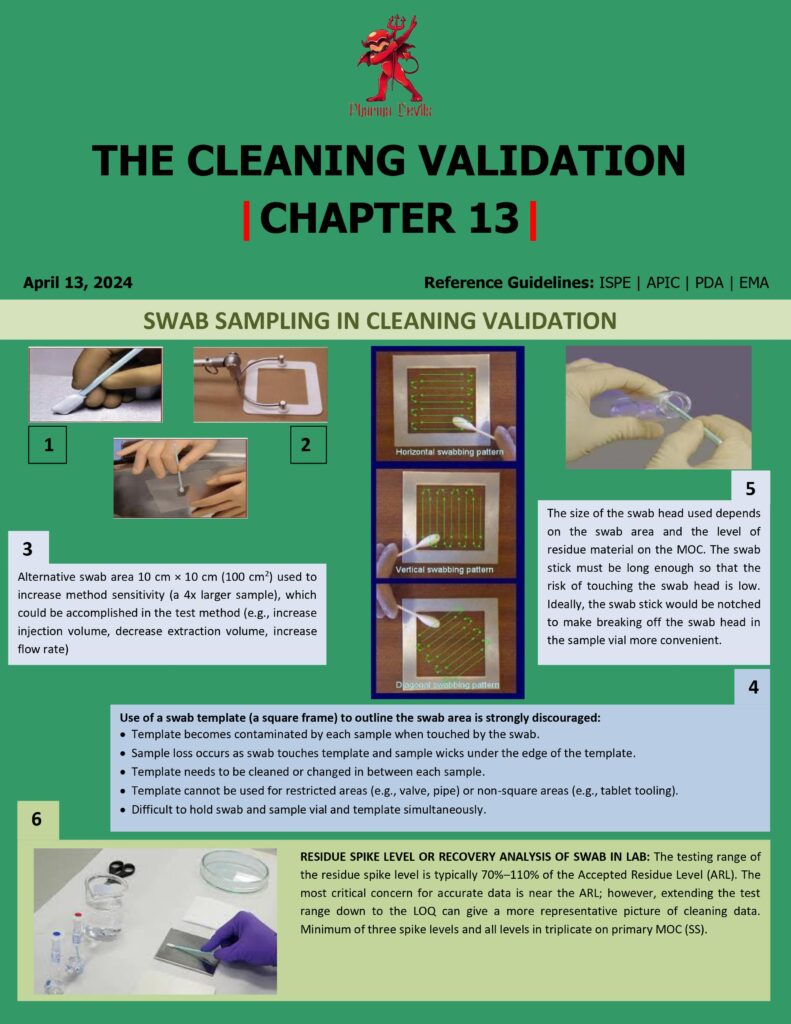

A typical swab study begins with selecting representative equipment and defining sampling points based on risk assessment (product potency/toxicity, solubility, stickiness, batch size, shared equipment, and cleaning method). Sampling locations should include at least one worst-case point per product-contact equipment train and should be justified in the protocol. Each swab sample is taken from a defined surface area (commonly 10 cm × 10 cm or another measured template) to allow calculation of residue per unit area. The swabbing material (e.g., polyester or polyurethane swab) and solvent/diluent must be compatible with the residue and surface and should not interfere with the analytical method.

Swab recovery is critical: recovery studies demonstrate the percentage of residue that can be removed from the surface by the swab and extracted into the sample solution. Recovery should be evaluated on representative coupons of the same material of construction (e.g., SS316L, glass, PTFE) using spiked known quantities across the expected range. Acceptance criteria are typically risk-based; the calculated residue results are corrected for recovery to avoid underestimating contamination.

Swab samples are analyzed using validated methods (e.g., HPLC/UPLC for actives, TOC for organics, conductivity/pH for detergents where applicable, or specific assays). Results are compared to established cleaning limits such as MACO (maximum allowable carryover) or HBEL/PDE-based limits, as well as visual cleanliness requirements. Proper documentation includes chain of custody, sample labeling, hold times, technician training, and investigation of any out-of-limit or atypical results. Swab sampling, combined with rinse sampling and visual inspection, provides strong evidence that cleaning processes are effective and reproducible.