HISTORY OF CLEANING VALIDATION IN PHARMA

Cleaning validation in the pharmaceutical industry grew gradually out of broader process validation and GMP expectations:

- Pre-1970s – “Clean but not proven”

Equipment was cleaned based on experience and good housekeeping practices, but there were no formal, documented requirements to prove that cleaning consistently removed residues or prevented cross-contamination. - 1970s – Birth of validation concepts

In 1978, US cGMP regulations explicitly required appropriate equipment cleaning and maintenance for finished pharmaceuticals, setting the legal foundation for later cleaning validation expectations.Wikipedia

In 1979, FDA officials Ted Byers and Bud Loftus formally introduced the broader concept of process validation to improve the quality of sterile products; cleaning later became one of the associated processes to be validated.Wikipedia - 1980s–early 1990s – First formal guidance

As multi-product facilities became common and cross-contamination risks were recognized, regulators started focusing on documented evidence of cleaning effectiveness.

This period saw early industry practice around simple, general limits (e.g. 10 ppm carryover or 1/1000 of the minimum daily dose), visual cleanliness checks, and basic swab/rinse sampling, but with limited harmonization.usp-pqm.org - 1993 – FDA “Guide to Inspection of Cleaning Validation”

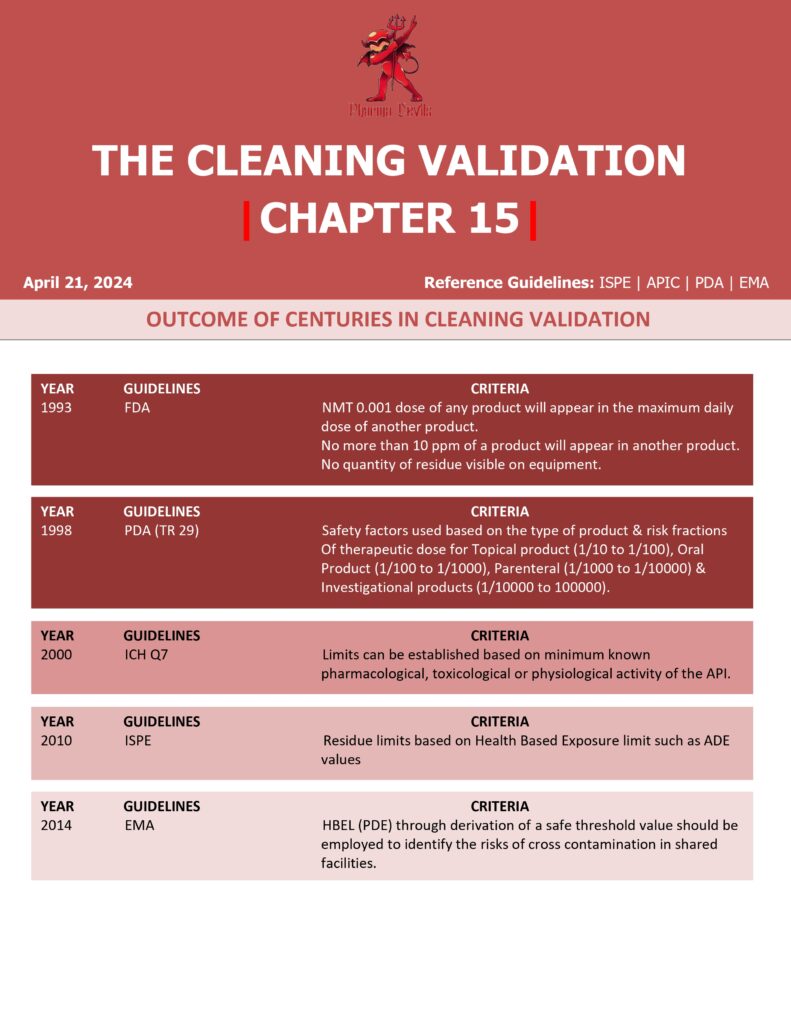

The FDA Guide to Inspection of Validation of Cleaning Processes (1993) was a turning point. It:- Defined expectations for written procedures, documented studies, and validation reports

- Emphasized validated analytical methods, worst-case product selection, and swab/rinse sampling strategies

- Popularized the 10 ppm and 1/1000th therapeutic dose concepts as informal acceptance criteria.

- Late 1990s–2000s – Globalization and harmonization

- APIC Cleaning Validation Guides (1999–2000) provided detailed approaches for API plants, including MACO (Maximum Allowable Carryover) calculations based on therapeutic dose or toxicity (NOEL/LD₅₀).

- ICH Q7 (APIs, 2001) reinforced the need for validated cleaning processes and justified residue limits that are practical, achievable, verifiable, and based on the most deleterious residue.

- The concept of matrix approaches, worst-case product selection, and formal SOP-driven cleaning validation programs became standard in pharma worldwide.PNR Journal

- 2000s–2010s – Risk-based, science-based era

- ICH Q9 (Quality Risk Management, 2006) pushed industry toward systematic, documented risk assessment (FMEA, HACCP, etc.) applied to cleaning validation, including identification of “hard-to-clean” equipment and high-risk products.

- ISPE Risk-MaPP (2009) and the EMA HBEL/PDE guideline (2014) shifted acceptance criteria from simple 10 ppm rules to health-based exposure limits (HBEL/PDE/ADE), especially for potent and highly hazardous substances in shared facilities.

- 2010s–Present – Lifecycle and continuous verification

Recent practice treats cleaning validation as a lifecycle activity, aligned with ICH Q8–Q10 principles:- Development of cleaning processes using science and lab data

- Initial qualification (PPQ-style cleaning validation runs)

- Ongoing verification through routine monitoring, visual checks, analytical testing trends, and periodic review

Modern expectations emphasize data-driven, statistically sound protocols and integration of cleaning validation with overall contamination control strategy and quality risk management.

In summary, the history of cleaning validation in pharma shows a clear evolution:

from informal cleaning and simple visual checks, to formal validation with fixed empirical limits, and now to risk- and health-based, lifecycle-managed cleaning programs driven by global guidelines (FDA, EMA, ICH, PIC/S, ISPE) and robust scientific justification of acceptance limits.