A lifecycle approach to Cleaning Validation treats cleaning as a controlled process from design through routine operation, not a one-time study. It aligns with GMP expectations for science- and risk-based validation and supports sustained compliance.

1) Process and product understanding

Start by mapping the equipment train, product contact surfaces, and all cleaning steps. Identify hard-to-clean locations (dead legs, valves, spray shadows, gaskets) and understand residue risks: API potency/toxicity, solubility, stickiness, degradation, bioburden/endotoxin risk, and cleaning agent residues. Define worst-case products (low solubility, high potency, high batch size, strong staining, high carryover risk) and worst-case equipment.

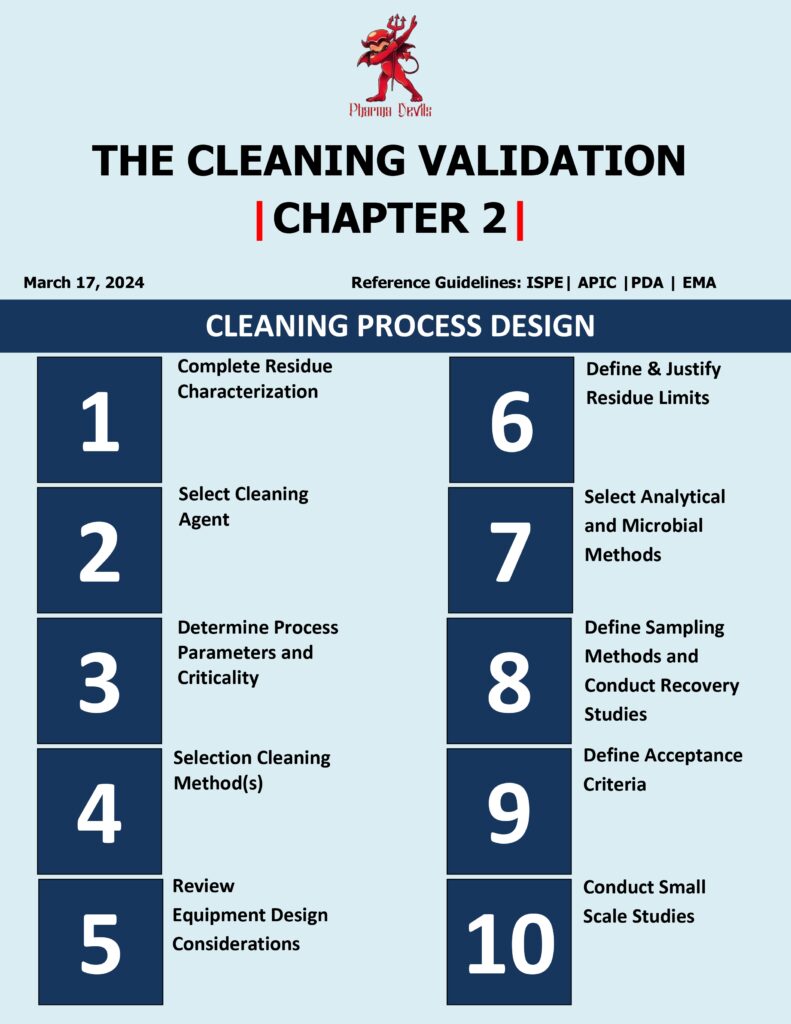

2) Cleaning process design (development)

Develop the cleaning procedure (manual/CIP/COP): detergent type and concentration, temperature, flow rate/turbulence, contact time, mechanical action, and rinse strategy. Generate development data to show residue removal across operating ranges. Establish holding times (dirty hold and clean hold), and define pre-cleaning if required.

3) Analytical and sampling strategy

Select appropriate methods (e.g., HPLC/UV/TOC/conductivity) with suitable LOQ at or below limits. Choose sampling methods: swab (localized worst-case) and/or rinse (overall system). Conduct swab recovery studies and sampling procedure training to ensure consistency.

4) Establish acceptance limits

Set health-based limits using HBEL/PDE where available, or justified alternatives. Convert limits into surface limits (e.g., µg/cm²) considering shared surface area, batch size, and maximum daily dose. Define limits for cleaning agent residues, bioburden/endotoxin (when applicable), and visual cleanliness.

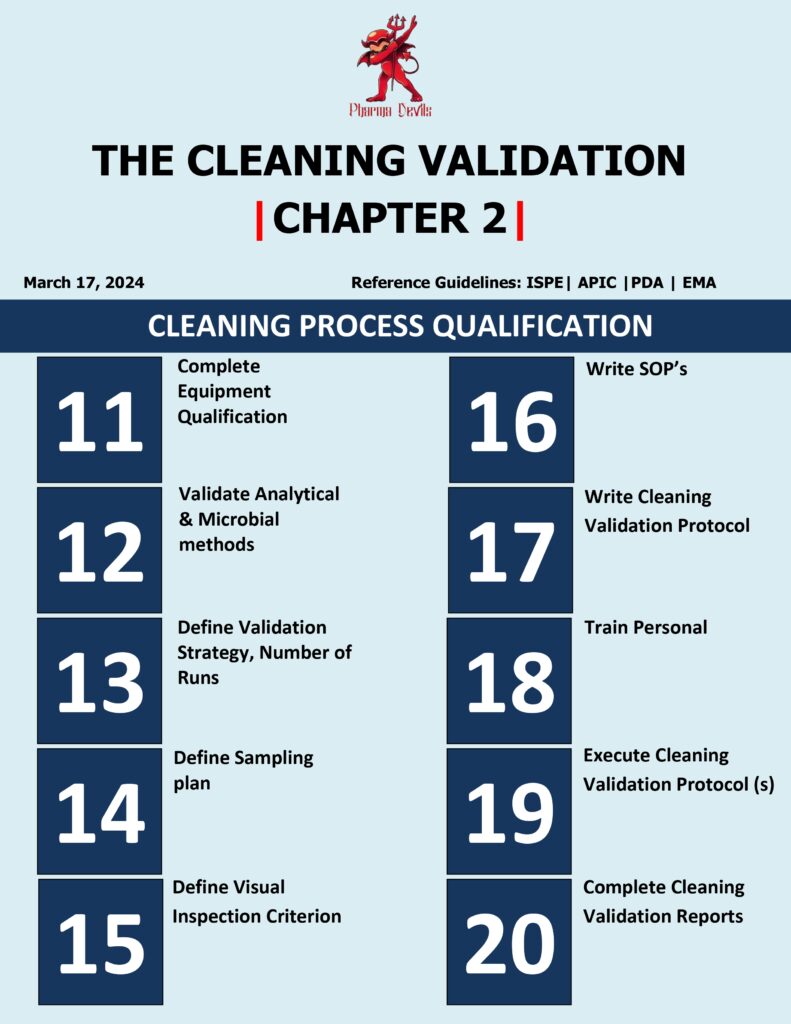

5) Performance Qualification (PQ)

Execute PQ on the validated procedure under routine conditions, typically three consecutive successful cleanings for each worst-case scenario, including planned dirty/clean hold times. Verify critical parameters and document deviations and corrective actions.

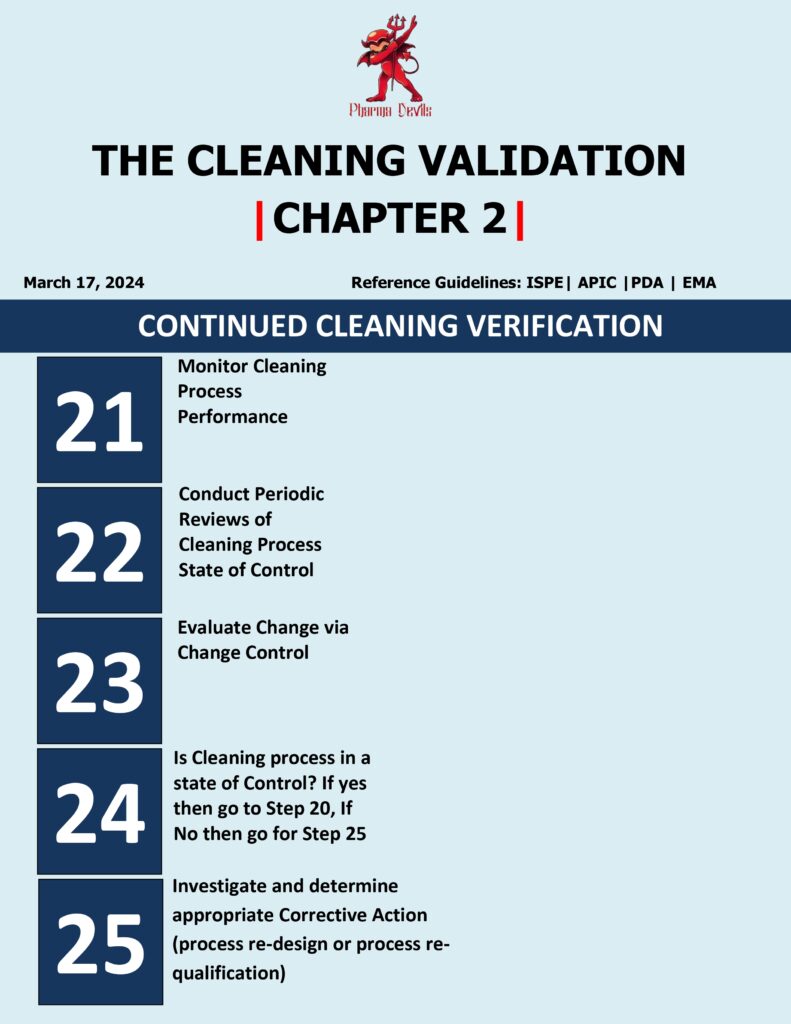

6) Continued verification

Maintain control using periodic monitoring: trending swab/rinse results, visual checks, CIP cycle parameter review, calibration, preventive maintenance, change control, and revalidation triggers (new product, new detergent, equipment modification, limit change, abnormal results). This stage ensures cleaning remains in a state of control throughout the product lifecycle.