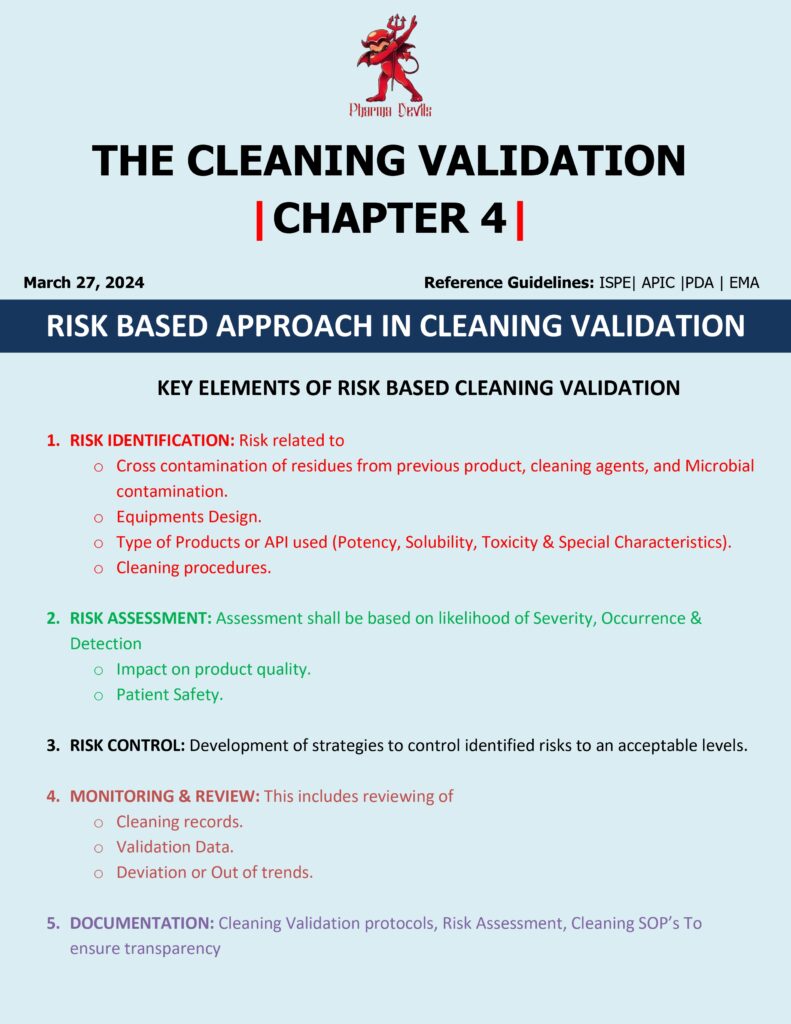

A risk-based approach (RBA) in cleaning validation applies Quality Risk Management principles to focus validation effort on what most impacts patient safety and product quality. Instead of validating “everything the same way,” you rank risks and design your strategy (worst-case selection, sampling, limits, and verification frequency) proportionate to those risks.

1) Define the risk question and scope

Start by mapping the equipment train, product-contact surfaces, utilities (CIP skids, hoses, transfer lines), and where residues can be retained (gaskets, valves, dead-legs, filters). Define cleaning type (manual/CIP/COP), cleaning agents, and hold times.

2) Identify hazards (what could harm the next product/patient)

Typical hazards include:

- API/product carryover (toxicity/PDE, potency, sensitizers)

- Cleaning agent residues (detergent limits, TOC/conductivity endpoints)

- Microbiological risk (bioburden/endotoxin where applicable)

- Cross-contamination by equipment design (traps, roughness, crevices)

3) Risk ranking and worst-case selection

Use a justified scoring model (e.g., Severity × Occurrence × Detectability) to rank:

- Product factors: PDE/ADI, dose, solubility, stickiness, degradation

- Process factors: campaign length, batch size, temperature, viscosity

- Equipment factors: surface area, complexity, hard-to-clean locations

Select worst-case products and worst-case equipment for validation. Apply grouping/bracketing only when equivalence is scientifically justified (same chemistry, same cleanability challenge, same equipment design, same cleaning process).

4) Design a risk-based sampling plan

Prioritize hard-to-clean locations and surfaces most likely to retain residues. Choose swab vs rinse based on accessibility and residue behavior. Include recovery studies, sample stability, and method sensitivity (LOD/LOQ well below limits).

5) Set risk-based acceptance criteria and controls

Define limits using MACO (PDE-based) as primary rationale; use visual as supportive. Set alert/action levels, trending rules, and define when to escalate (repeat cleaning, investigation, CAPA).

6) Continued verification and change control

High-risk scenarios (highly potent/toxic APIs, complex equipment, manual cleaning, long holds) require more frequent verification and tighter controls. Any change in product, detergent, equipment, cycle parameters, or hold time triggers risk reassessment and potential revalidation.