Worst-case selection in cleaning validation is a structured, risk-based approach used to choose the most challenging product, equipment, and process conditions to demonstrate that the cleaning procedure is effective for all routine manufacturing scenarios. The goal is to validate one cleaning process that provides assurance across a defined product family or equipment train, minimizing redundant studies while maintaining patient safety and GMP compliance.

1) Product-related worst case (Residue risk):

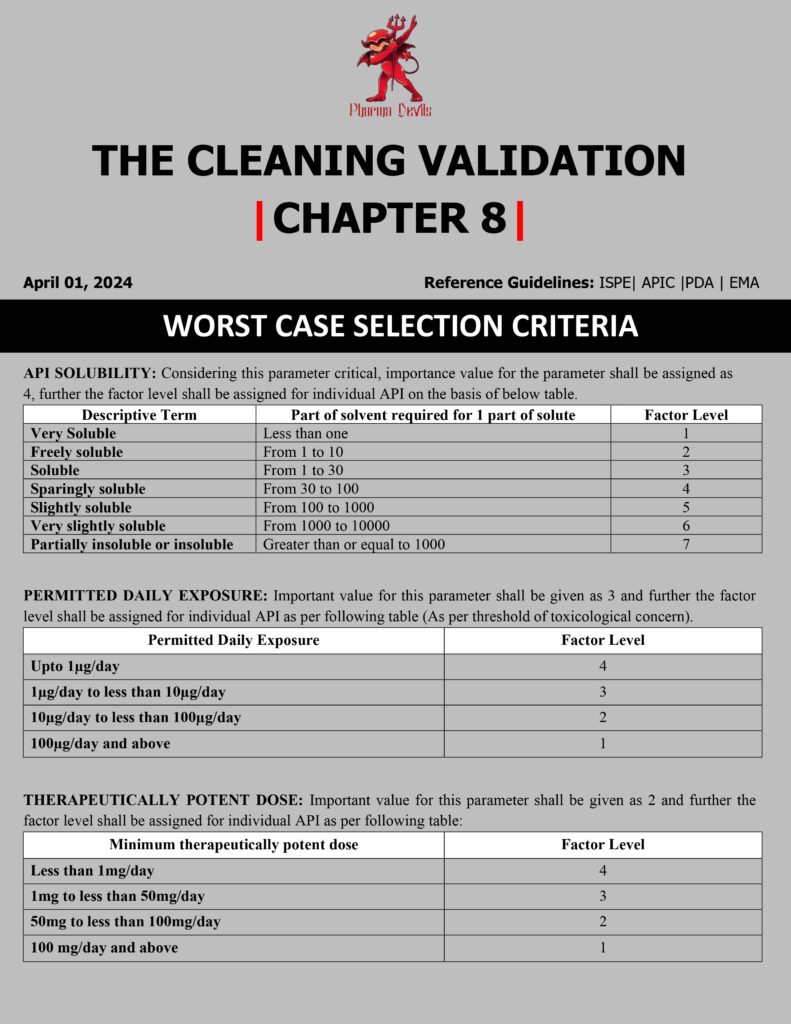

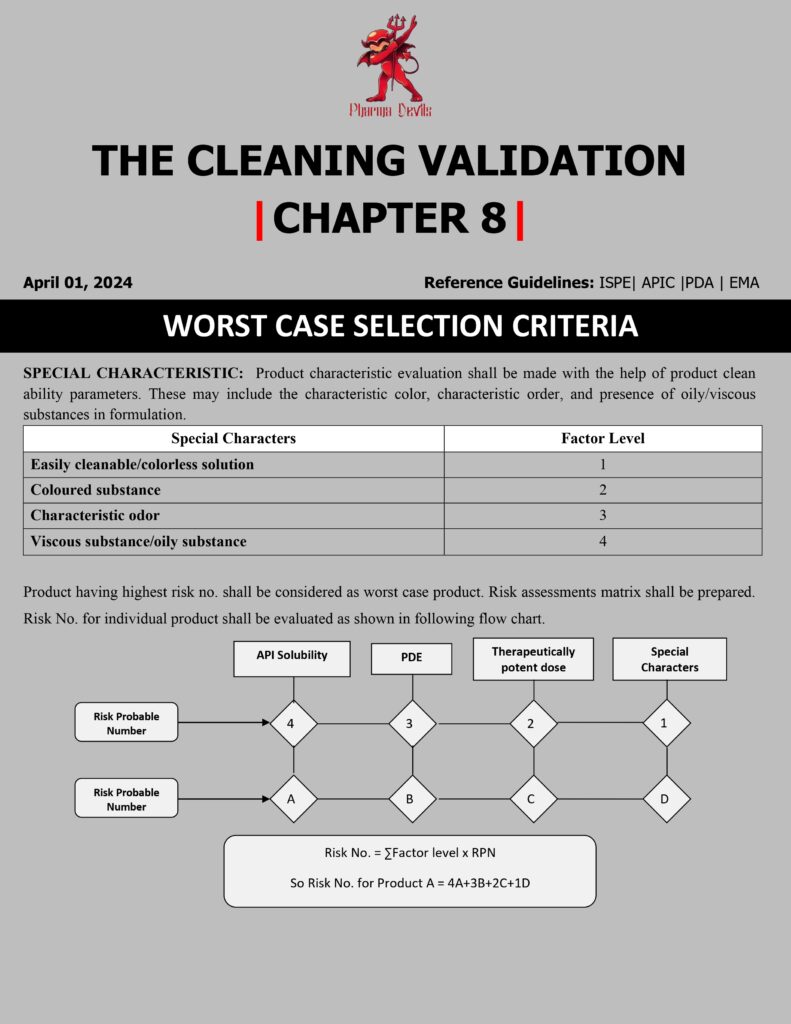

Select products with the highest risk of carryover based on potency/toxicity (HBEL/PDE), low therapeutic dose, and strong pharmacological activity. Consider products with poor solubility in cleaning media, high viscosity, stickiness, high concentration, or tendency to degrade and form difficult residues. Products with strong color, odor, or adherence to stainless steel, gaskets, or plastic parts may represent worst-case residues. Also evaluate formulation complexity (suspensions, ointments, gels) and excipients that are hard to remove (e.g., polymers, waxes, surfactants).

2) Equipment and surface worst case (Cleanability):

Choose equipment trains and locations that are most difficult to clean: long transfer lines, elbows, valves, pumps, filters, spray-ball shadow areas, dead legs, small-bore tubing, gasket grooves, and rough or damaged surfaces. Consider material of construction (SS316L vs. elastomers), surface finish, and age/condition of equipment.

3) Process-related worst case (Soil load and cleaning challenge):

Include maximum batch size, highest product load, longest campaign length, and maximum hold time before cleaning (“dirty hold time”). Longer hold times often increase residue hardness. Consider the most challenging operating temperatures that may bake residues onto surfaces, and the lowest effective cleaning parameters (minimum detergent concentration, temperature, flow, and contact time) within defined ranges.

4) Cleaning agent and method worst case:

If multiple detergents or methods exist, validate under the least effective yet allowed conditions (minimum time/temperature/concentration) and verify adequate rinsing to prevent detergent carryover.

5) Analytical worst case (Detectability):

Prefer residues that are hardest to detect analytically or have the tightest acceptance limits. Ensure validated methods with appropriate LOQ, specificity, and recovery.

Final worst-case selection must be justified with documented scoring/logic, based on risk assessment, historical deviations, and development data, and approved through QA.