A Visible Residue Limit (VRL) is the maximum amount of residue on a product-contact surface that is just visible to the unaided eye under defined viewing conditions. It is mainly used to support visual inspection as a verification tool, to justify “visually clean” criteria, and to provide a practical check alongside analytical limits (HBEL/MACO). VRL does not replace health-based limits; it complements them.

How VRL is developed

- Choose worst-case residues

Select representative materials that are hard to clean or easy to see: API, product blend, colored components, or detergent residues (if relevant). Consider residues after drying, heat exposure, or typical dirty hold time. - Define test surfaces

Use actual equipment finish where possible (e.g., SS316L with specified Ra), and include gaskets, glass, or coated surfaces if they are part of the train. Surface condition affects visibility. - Standardize viewing conditions

Document lighting intensity (lux), light angle, background contrast, viewing distance (e.g., 30–60 cm), inspection time, and whether magnification is allowed. Train inspectors and include eyesight requirements where applicable. - Prepare residue coupons

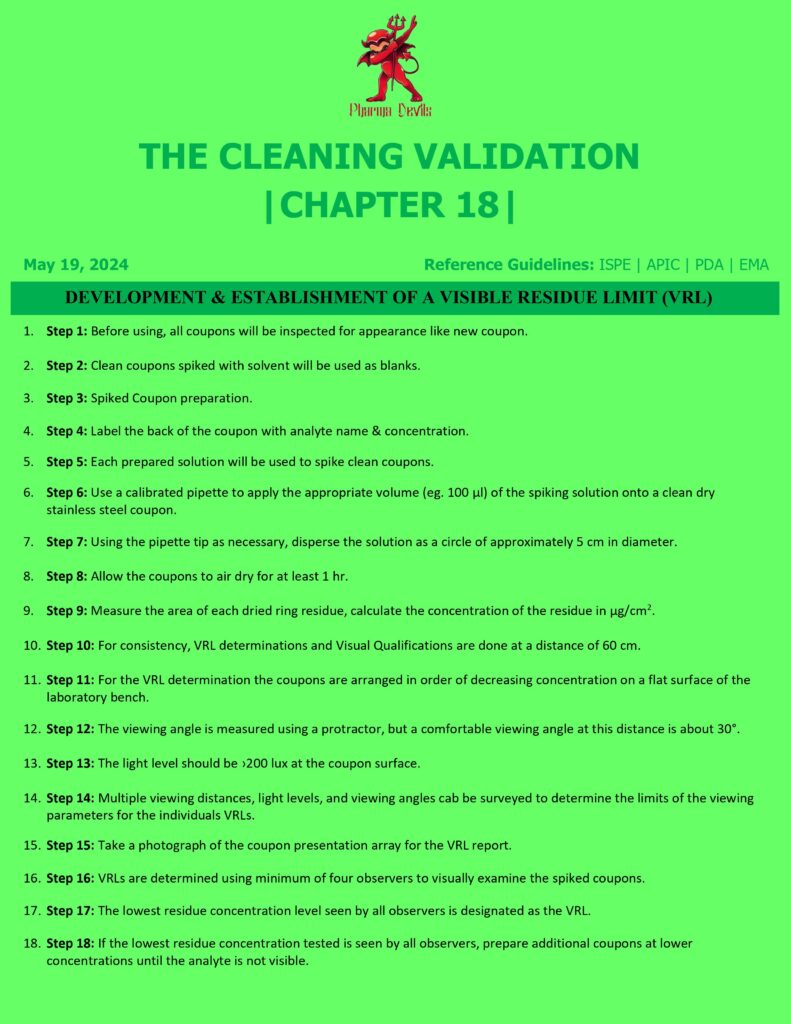

Apply known quantities of residue to a defined area (often 25 cm² or a template size), dry under controlled conditions, and create a series of levels (e.g., geometric steps). Include replicates. - Determine the visibility threshold

Have multiple trained observers inspect blinded samples. The VRL is typically set at the lowest residue level consistently detected (e.g., detected by ≥50–75% of observers, depending on your SOP). Record inter-observer variability. - Convert to a usable limit

Express VRL as µg/cm² (or mg/100 cm²) and link it to routine inspection expectations: “No visible residue under defined conditions.”

Establishing routine use

- Use VRL to qualify visual inspection capability and to validate inspection conditions.

- Compare VRL with the calculated analytical limit: if the HBEL/MACO limit is lower than VRL, analytical testing governs. If VRL is lower, visual inspection becomes a strong, conservative control.

- Reassess VRL after changes in formulation, surface finish, lighting, or inspection method, and trend visual inspection findings as part of continued verification.