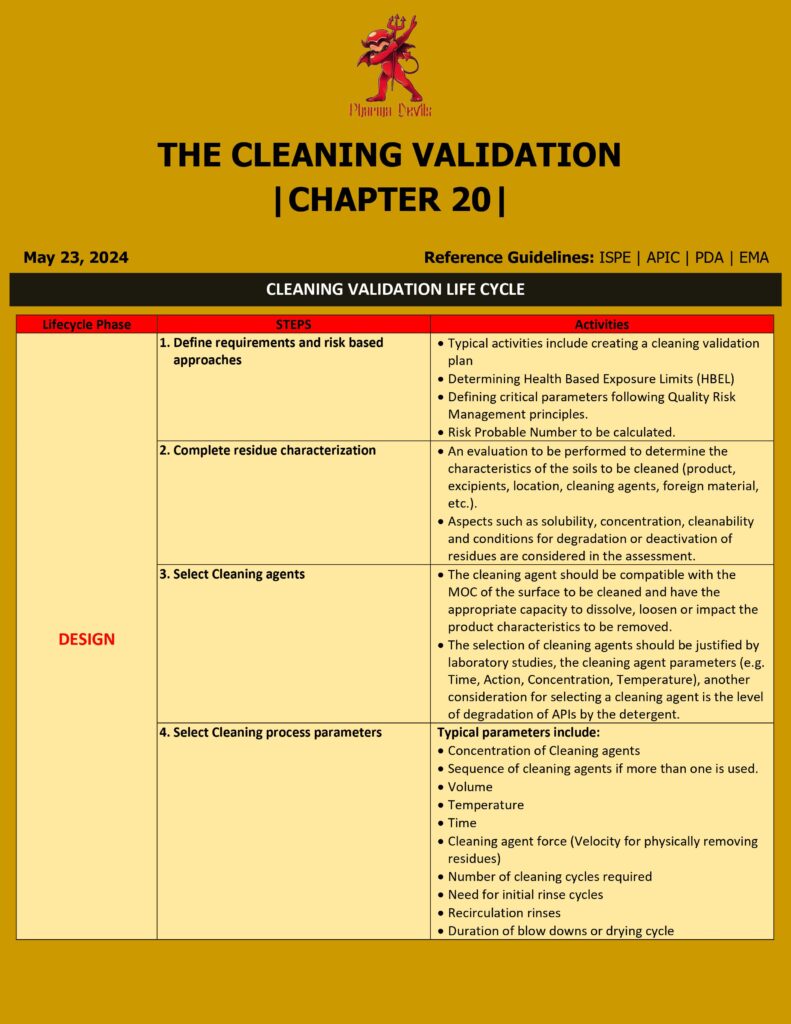

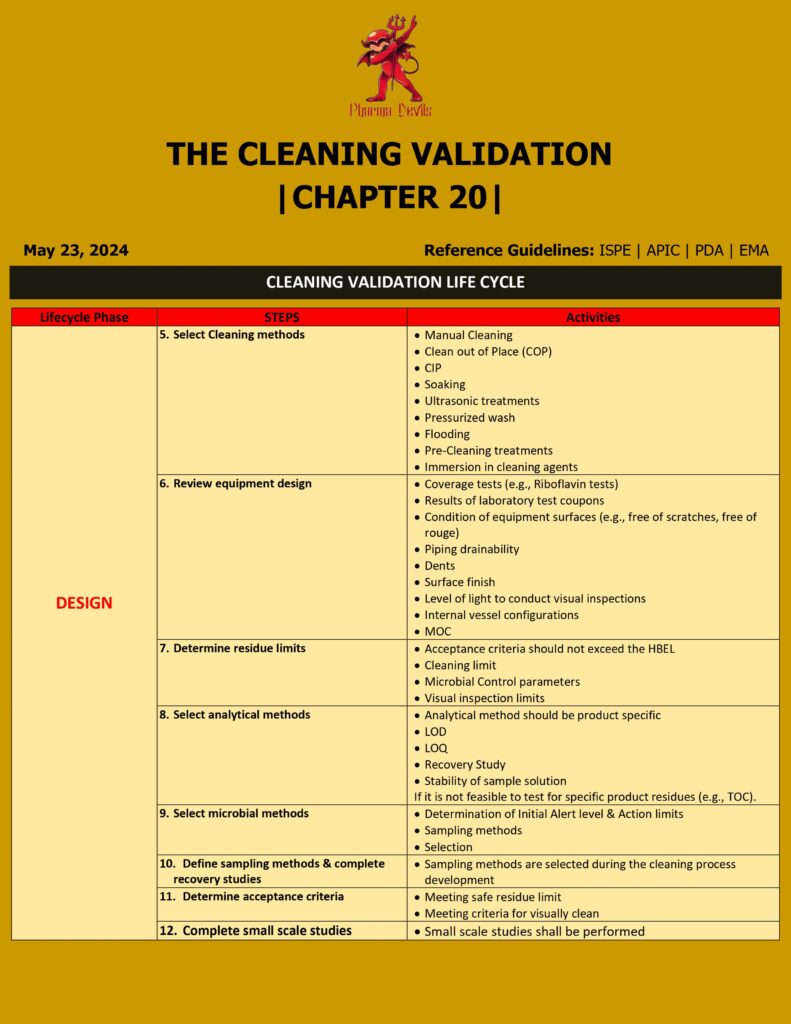

1. Process Design (Stage 1)

Goal: Design and understand the cleaning process so it can consistently remove product, detergent, and microbial residues to an acceptable level.

Key activities:

- Define scope

- Which equipment trains?

- Which products / worst-case products?

- Shared vs dedicated equipment?

- Risk assessment

- Identify worst-case products based on:

- Lowest therapeutic dose

- Highest toxicity

- Lowest solubility

- Sticky / highly adsorptive nature

- Identify hard-to-clean equipment parts (dead legs, gaskets, valves).

- Identify worst-case products based on:

- Set acceptance limits

- Health-based limits (HBEL / PDE-based MACO).

- Microbial & endotoxin limits (if applicable).

- Detergent residue limits.

- Choose and define cleaning process

- Manual vs automated (CIP/COP).

- Detergent type, concentration, contact time, temperature, number of rinse cycles.

- Equipment disassembly requirements.

- Analytical method development

- Swab and/or rinse sampling.

- Specific methods (HPLC/UPLC) vs non-specific (TOC, conductivity).

- Ensure methods are stability-indicating where needed.

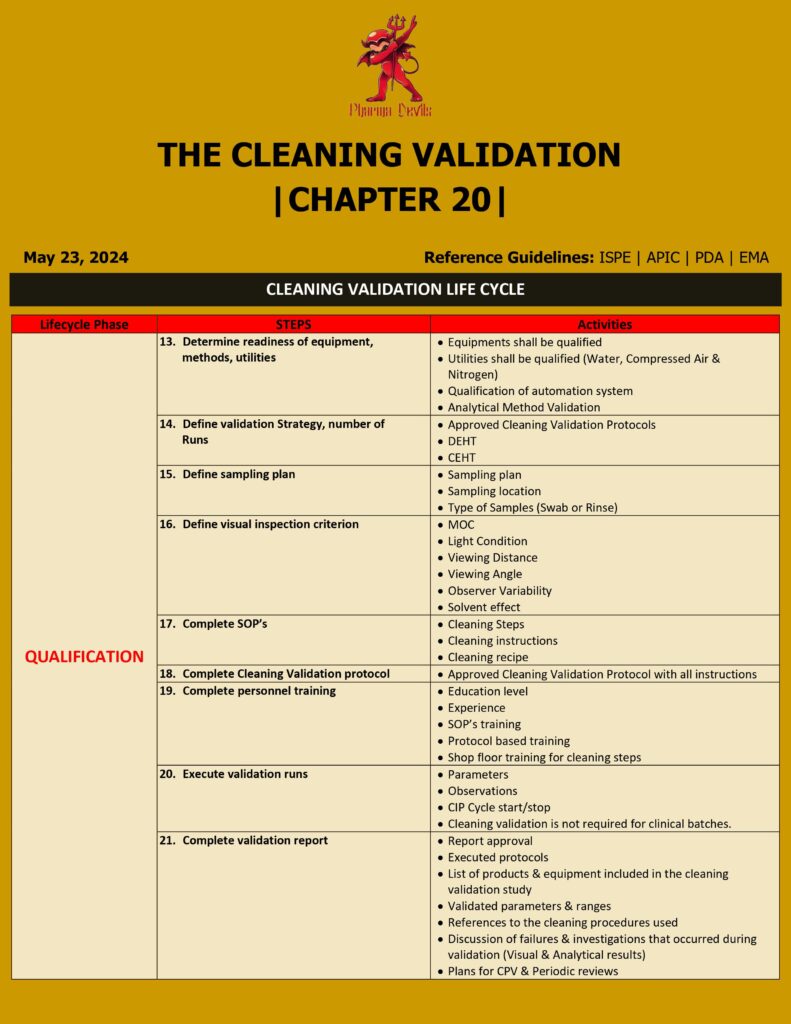

2. Process Qualification / Validation (Stage 2)

Goal: Demonstrate and document that the designed cleaning process works as intended under routine conditions.

Typical steps:

- PQ protocol

- Define number of runs (often 3 consecutive successful runs per equipment train/worst-case).

- Define sampling locations (worst-case / hardest-to-clean locations).

- Define hold times (soils drying, dirty hold, clean hold).

- Execute cleaning validation runs

- Run the full cleaning procedure as per SOP.

- Document:

- Batch details (previous product, strength).

- Equipment IDs.

- Operators.

- Exact parameters (time, temp, detergent concentration).

- Sampling & testing

- Swab and/or rinse from defined locations.

- Visual inspection (no visible residues).

- Lab analysis vs acceptance criteria (API, degradants, detergent, bioburden, endotoxin).

- Evaluate data & conclude

- All results within limits.

- No trends toward failure.

- Document deviations and CAPA if any.

- Approve cleaning process and finalize validated status.

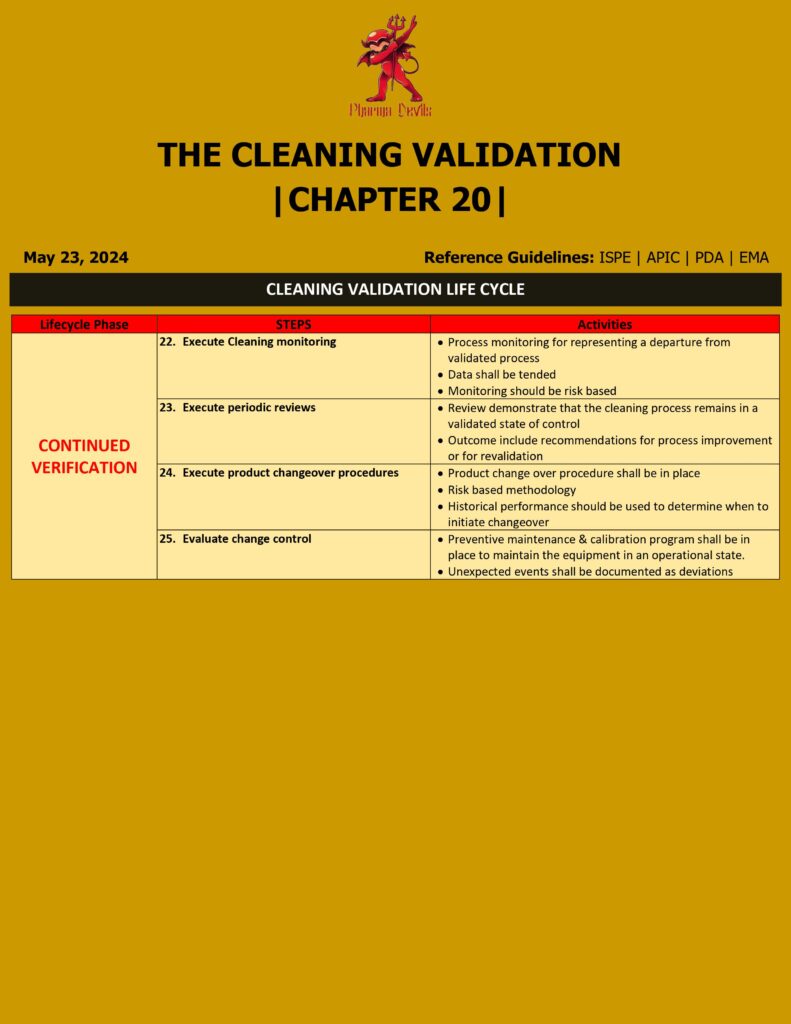

3. Continued / Ongoing Verification (Stage 3)

Goal: Maintain and demonstrate control over time, ensuring the cleaning process remains capable as products, equipment, or conditions change.

Ongoing activities:

- Routine monitoring

- Periodic verification (e.g., 1–2 runs per year per equipment train, or risk-based).

- Trending of results (e.g., TOC values, residual levels).

- Change control

- Re-assess Cleaning Validation when:

- New product (especially more toxic / lower dose).

- New equipment or surface material.

- Changes in cleaning agents, parameters, or SOP.

- Changes in batch size or campaign size.

- Re-assess Cleaning Validation when:

- Periodic review

- Review cleaning validation every 1–3 years:

- Trends, OOS / OOT.

- Deviations / incidents (cross-contamination, visible residues).

- Effectiveness of CAPAs.

- Confirm HBEL/PDE values are still appropriate with any new toxicology data.

- Review cleaning validation every 1–3 years:

- Continuous improvement

- Optimize:

- Reduced water / detergent usage.

- Shorter cleaning times.

- Better ergonomics / safety for operators.

- Implement new technology (e.g., better CIP design, new detergents, PAT/online monitoring).

- Optimize:

How it fits together (Simple View)

Life Cycle = Design → Qualify → Monitor & Improve

- Design the cleaning process

→ Understand risks, worst-cases, acceptance limits, and procedures. - Qualify / validate the process

→ Prove with data (multiple runs) that cleaning is effective and reproducible. - Verify & control over time

→ Periodic checks, change control, and continuous improvement.