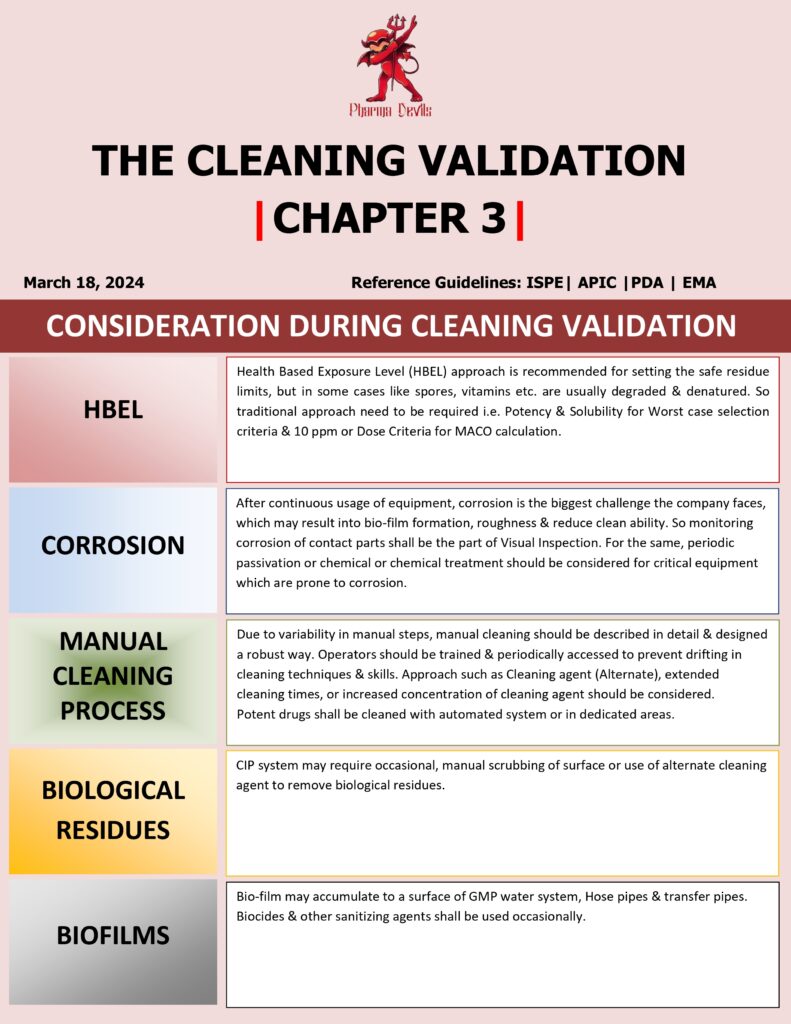

Cleaning validation demonstrates that approved cleaning procedures consistently remove product residues, cleaning agents, and bioburden (where applicable) to predefined acceptance limits. Key considerations should be planned upfront and justified in a risk-based manner.

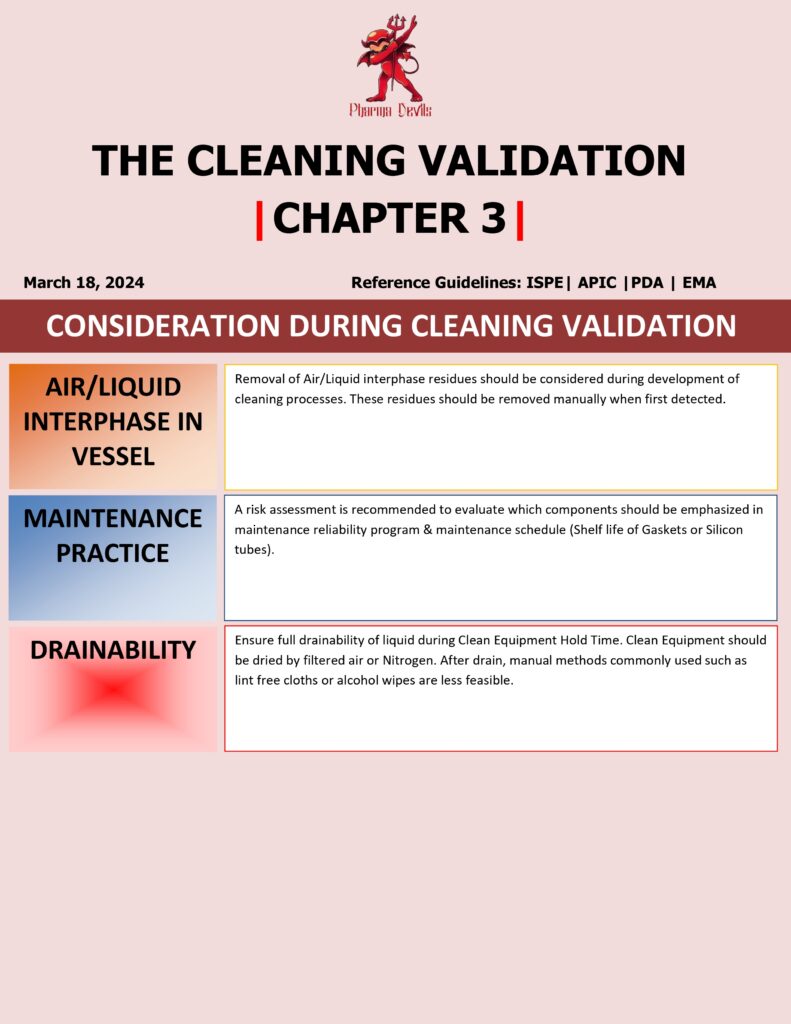

Start with a well-defined scope: equipment train boundaries, product families, shared utilities, and surfaces to be covered. Use worst-case selection based on toxicity/PDE, solubility, potency, cleanability, batch size, equipment complexity, and campaign length. Define the dirty hold time (DHT) and clean hold time (CHT), and validate them if they can influence residue adhesion or microbial growth.

Ensure the cleaning procedure is standardized and controlled: detergents/cleaning agents (type, concentration, contact time), water quality (PW/WFI), temperature, flow/pressure, mechanical action, rinse volumes, and drying. For CIP/SIP systems, verify spray coverage, cycle parameters, conductivity/TOC endpoints (if used), and any manual interventions. For manual cleaning, address operator variability through training, clear visual aids, and defined tools (brush type, direction, strokes, disassembly points).

Sampling strategy is critical. Choose swab, rinse, or placebo/flush sampling based on equipment design and residue risk. Identify hard-to-clean locations (gaskets, dead legs, valves, corners, transfer lines) and justify sampling points. Establish recovery studies (swab/rinse recovery and extraction efficiency), sample storage stability, and transport conditions. Use validated analytical methods with suitable LOD/LOQ below the acceptance limit; confirm specificity against detergents and degradation products.

Acceptance criteria must be scientifically justified: MACO (based on PDE/ADI), 10 ppm (legacy—avoid as sole rationale), visual cleanliness (supportive, not primary), and microbial/endotoxin limits for non-sterile/sterile applications. Define alert/action levels for routine monitoring and trending.

During execution, document each run: equipment status, product history, cleaning parameters, deviations, and results. Perform deviation investigations with root cause analysis and CAPA if limits are exceeded or trends worsen. Finally, implement a continued cleaning verification program: periodic swabbing/rinse testing, change control triggers (new product, detergent, equipment modification), and periodic review of capability (e.g., Cpk) to maintain a state of control.