1. Basic Concept

- Manual decartoning

Operators open cartons and remove ampoules by hand, placing them into SS trays/baskets. - Decartoning machine

Automated or semi-automatic equipment that feeds, opens, and unloads ampoules from cartons/trays with minimal manual handling.

2. Comparison Table

| Aspect | Manual Decartoning | Decartoning Machine |

|---|---|---|

| Manpower requirement | High – multiple operators needed for big batches | Low – 1–2 operators to load, monitor, and unload |

| Speed / Throughput | Moderate, depends on operator skill & fatigue | High, consistent output (good for large-scale filling) |

| Consistency | Variable – human dependent | Highly consistent, repeatable cycle |

| Breakage risk | Higher – human handling, fatigue, slips | Lower if well-designed; uniform movements |

| Glass particle risk | Higher if handling is rough or careless | Lower; controlled motion, less shock to ampoules |

| Mix-up risk | Higher if multiple products handled in same area | Lower – usually dedicated settings/product per run |

| Contamination risk | More hand contact, more chances of poor technique | Reduced direct handling; easier to maintain routine |

| Traceability | Relies on manual log entries & tray labeling | Often better – can integrate counting / sensors / print |

| Ergonomics | Risk of strain (repetitive movements, bending) | Better – operators mostly supervise & load/unload |

| Flexibility | Very flexible – easy to change ampoule size/pack | Less flexible – change parts/adjustment may be needed |

| Learning / Training | Simple – short training period | More technical – training on settings, alarms, safety |

| Equipment cost (CAPEX) | Very low – just tables, trays, cutters | High – dedicated decartoning equipment |

| Running cost (OPEX) | Higher labour cost; minimal maintenance | Lower labour cost; higher maintenance & spare parts |

| Space requirement | Small area – table + trays | Larger footprint – machine + conveyor / infeed area |

| Cleaning & changeover | Simple – wipe tables, clean trays manually | Scheduled cleaning & change parts; more formalized |

| Qualification effort | Mainly procedural (SOP) | Full IQ/OQ/PQ of machine, alarms, safety, interlocks |

| Best suited for | Small/medium batches, low automation plants | Medium/large batches, high-speed filling lines |

3. When to Prefer Manual Decartoning

- Small or low-volume batches

- Many product/ampoule sizes with frequent changeovers

- Plants where CAPEX is limited

- Backup / contingency when machine is down

- Early phase / development batches where process is still evolving

4. When to Prefer a Decartoning Machine

- High-volume commercial production

- Multiple shifts with tight timelines

- Need to reduce glass breakage and particle load before washing/sterilization

- Targeting lower manpower and improved ergonomics

- Strong focus on automation, counting accuracy, and traceability

MANUAL DECARTONING OF AMPOULES

5.1 Purpose

To describe the procedure for manual decartoning of ampoules in a controlled manner to prevent mix-ups, breakages and contamination.

5.2 Scope

This procedure applies to all ampoule packs received in cartons for use in sterile/aseptic filling in __________________ Department.

5.3 Responsibilities

- Production Operator:

- Perform manual decartoning as per this SOP.

- Ensure correct identification and segregation of good/rejected ampoules.

- Production Supervisor:

- Verify decartoned quantity, reconciliation and labeling.

- QA Officer:

- Perform line clearance and in-process checks as applicable.

5.4 Procedure

5.4.1 Pre-requisites

- Ensure line clearance of the decartoning area is carried out and documented as per line clearance SOP.

- Verify that the following are available and clean:

- Decartoning table

- SS trays / perforated baskets

- Labeled containers for rejected/broken ampoules

- Status labels (e.g. “UNDER PROCESS”, “REJECTED”)

- Confirm product details (Product name, Batch No., Strength/volume, ampoule size) against:

- Dispensing slip / material issue note

- Carton label

- Record starting details in Decartoning Log / BMR.

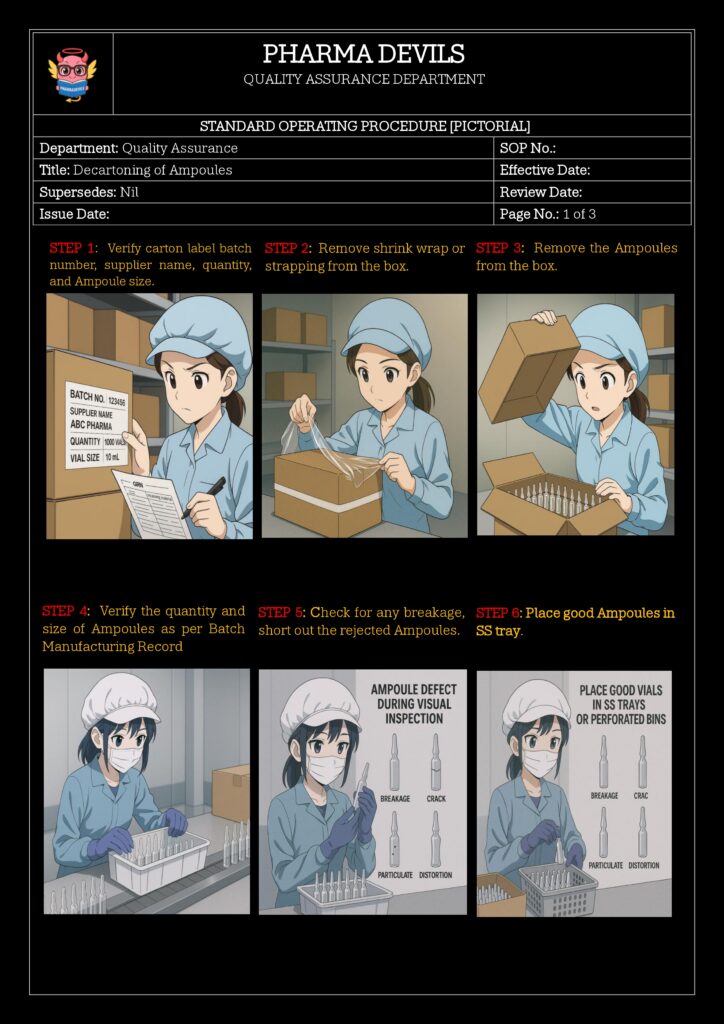

5.4.2 Manual Decartoning Steps

- Bring the required number of cartons to the decartoning table as per material movement SOP.

- Handle one product and one batch at a time.

- Open each carton carefully using a safety cutter or scissors, avoiding contact with ampoules.

- Remove inner trays/liners containing ampoules and place them gently on the table.

- Lift ampoules manually from the tray and place them upright into clean SS trays or baskets.

- Avoid knocking ampoules against each other or the tray edges to minimize breakage and glass particles.

- Visually inspect ampoules during transfer for:

- Broken or cracked ampoules

- Chipped necks or tips

- Major printing or glass defects

- Segregate any defective ampoules into the “REJECTED/BROKEN” container.

- Continue until the required quantity for the batch is decartoned.

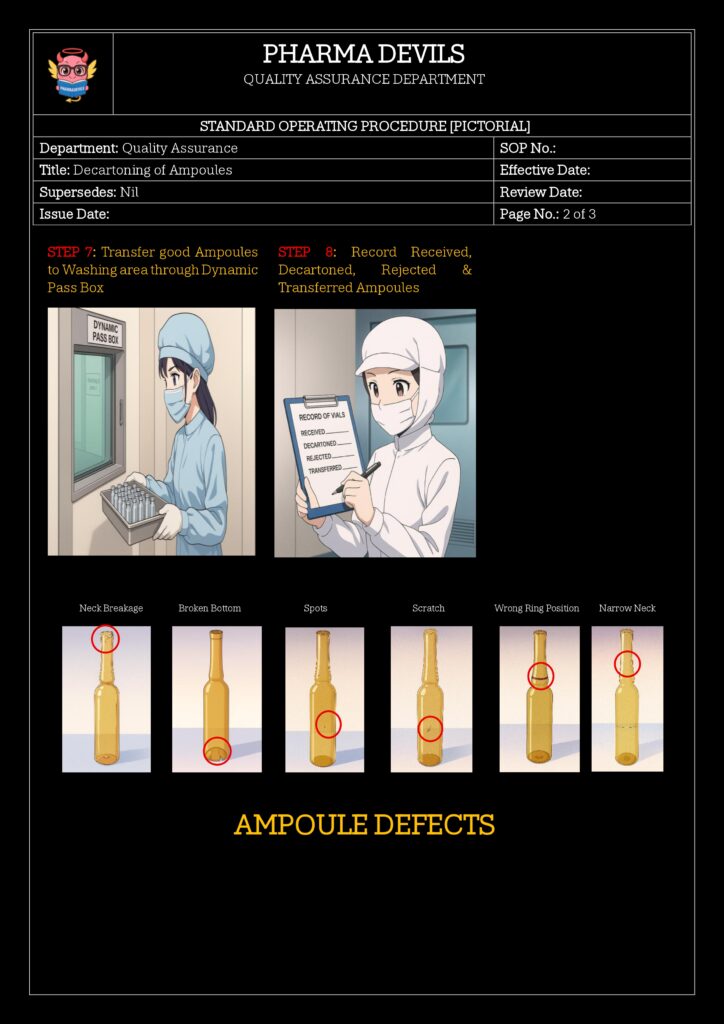

5.4.3 Post-Decartoning

- Count and record:

- Total ampoules received

- Total ampoules decartoned

- Total rejected/broken

- Ensure reconciliation is within defined limits as per BMR.

- Label each tray/basket of decartoned ampoules with:

- Product name

- Strength/volume

- Batch No. / Lot No.

- Quantity

- Date and time of decartoning

- Operator initials

- Apply appropriate status label (e.g. “TO BE WASHED”).

- Transfer the trays of ampoules to the next stage (e.g. washing) as per material handling SOP.

- Dispose of broken ampoules and glass waste as per glass waste disposal SOP.

5.5 In-Process Checks (Manual)

- Correct product/batch and ampoule size in use

- Decartoning area free from any other product

- Adequate labeling of trays and reject containers

- Reconciliation of good vs. rejected ampoules acceptable

5.6 Acceptance Criteria (Manual)

- No evidence of product mix-up.

- Glass breakage maintained within historical/validated limits.

- All trays properly labeled and traceable.

- All rejects recorded and disposed as per SOP.

6.0 DECARTONING OF AMPOULES USING DECARTONING MACHINE

6.1 Purpose

To describe the procedure for decartoning ampoules using an automatic/semi-automatic decartoning machine, ensuring controlled, efficient and low-breakage handling.

6.2 Scope

This procedure applies to all ampoule cartons processed through the Decartoning Machine (Equipment ID: _______) in __________________ Department.

6.3 Responsibilities

- Machine Operator (Production):

- Set up, operate and monitor the decartoning machine as per this SOP and equipment manual.

- Production Supervisor:

- Verify settings, output quantity and reconciliation.

- Engineering:

- Ensure availability and upkeep of machine (PM, breakdown support).

- QA:

- Line clearance, periodic audit and verification of process controls.

6.4 Procedure

6.4.1 Pre-requisites

- Ensure decartoning machine has undergone cleaning and line clearance for the new product/batch as per SOP.

- Confirm that change parts (if any) are installed for the specific ampoule size and carton type.

- Check that safety guards, interlocks and emergency stop are functional.

- Verify product details (Product, Batch, Strength, ampoule size) against BMR and carton labels.

- Record machine ID, product name, batch number, and starting carton count in Decartoning Log / BMR.

6.4.2 Machine Set-up

- Start the machine as per manufacturer’s Start-up procedure.

- Set parameters as applicable (e.g. conveyor speed, feed rate).

- Run the machine empty for a short time to check abnormal noise or vibration.

- Load a trial carton and observe:

- Carton feeding

- Opening/tearing mechanism

- Ampoule unloading path

- Discharge of decartoned ampoules into trays or conveyor

- Ensure ampoules are not falling from excessive height or colliding excessively.

6.4.3 Routine Operation

- Load cartons onto the machine in-feed as per defined loading pattern.

- Operate the machine within qualified speed range.

- Collect decartoned ampoules from the machine discharge into SS trays/baskets provided.

- Periodically perform visual inspection at discharge for:

- Broken or cracked ampoules

- Misaligned or jammed ampoules

- Carton pieces or foreign matter mixed with ampoules

- Remove broken ampoules and place them into “REJECTED/BROKEN” container.

- Monitor machine alarms / stoppages and inform Engineering in case of any recurring issues.

6.4.4 In-Process Checks (Machine)

Perform and record the following at defined frequency (e.g. start, every ___ minutes, and end):

- Count of ampoules per sample tray vs. machine counter (if available).

- Visual breakage rate: number of broken ampoules during defined interval.

- Confirmation that only one product/batch is being decartoned.

- Check that no carton pieces remain mixed with decartoned ampoules.

6.4.5 Post-Decartoning

- Stop machine as per standard shutdown procedure.

- Complete quantity reconciliation:

- Cartons loaded / ampoules expected

- Ampoules obtained

- Rejected/broken ampoules

- Label trays/baskets of decartoned ampoules with:

- Product name

- Strength/volume

- Batch/Lot No.

- Quantity

- Date/time of decartoning

- Operator initials

- Apply status label (e.g. “TO BE WASHED”).

- Remove residual ampoules, cartons and dust from the machine as per cleaning SOP.

- Dispose of broken ampoules and carton waste as per waste management SOP.

6.5 Acceptance Criteria (Machine)

- Machine operated within qualified speed and parameters.

- Breakage rate within validated limits and not higher than defined target.

- No mix-up of product, batch or ampoule size.

- Reconciliation between input (cartons) and output (ampoules + rejects) is within defined limits.

- All trays of decartoned ampoules are correctly labeled and traceable.

- No carton fragments or foreign matter present in decartoned ampoules.