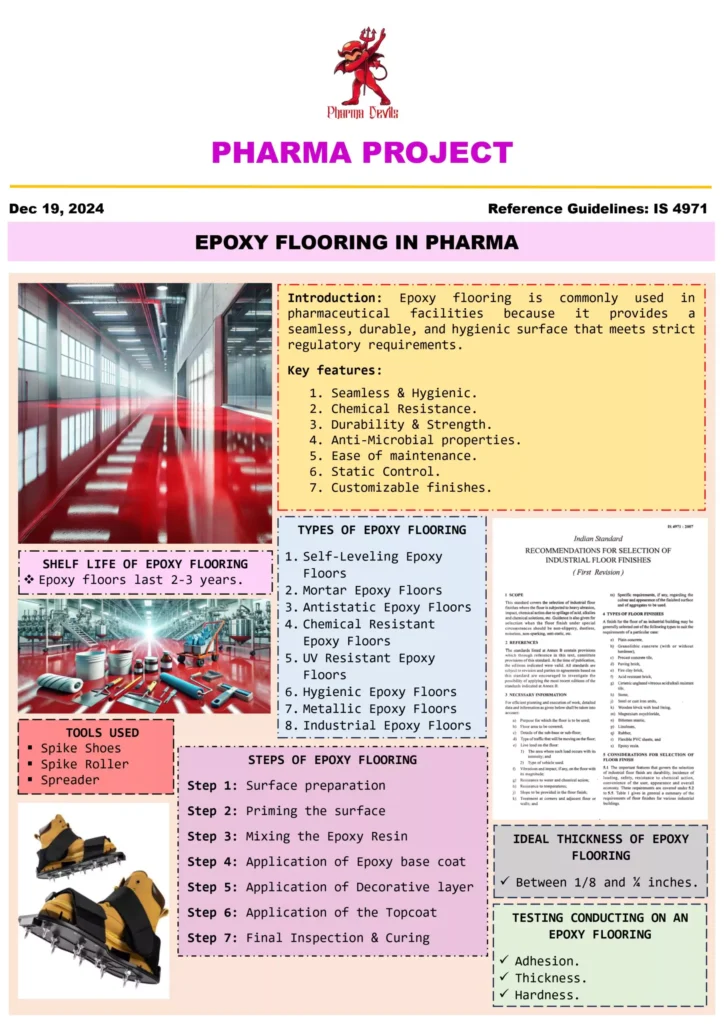

Epoxy flooring in pharma is a seamless, non-porous resin floor system used in manufacturing, packaging, QC labs, and warehouses to support GMP cleanliness, durability, and contamination control. Its main value is that it creates a surface that is easy to clean, resistant to chemicals, and minimizes dust generation—all critical for controlled environments.

Why epoxy is preferred in GMP areas

- Hygiene and cleanability: A properly installed epoxy floor has a smooth, joint-free surface that prevents trapping of dust, powders, and microbes. With coved skirting (curved floor–wall junction), cleaning becomes more effective and corners don’t accumulate residues.

- Chemical resistance: Epoxy resists many disinfectants, solvents, acids/alkalis used in pharma (cleaning agents, IPA, detergents). Selection depends on chemical exposure; for very aggressive chemicals, vinyl ester or polyurethane systems may be better.

- Mechanical strength: It withstands pallet movement, trolley traffic, and equipment loads. Heavy-duty epoxy systems include thicker build and wear-resistant topcoats.

- Contamination control: Anti-static (ESD) epoxy is used where powders and solvents create static risk and where electronic instruments need protection. Non-shedding, low-VOC systems help reduce particulate generation.

- Moisture and slip management: Textured topcoats can provide slip resistance in wash areas, while maintaining cleanability. Moisture vapor barriers are important where concrete has high moisture, preventing blistering and delamination.

Typical pharma specifications (practical expectations)

A pharma epoxy flooring specification usually defines:

- Surface finish: smooth matte/satin; pinhole-free; no cracks/voids.

- Coving: 50–100 mm cove up the wall (often higher in wet areas).

- Thickness: often 2–3 mm for light duty, 4–6 mm for heavy duty; depends on traffic and impact.

- Slope & drains: in wash areas, proper slope to drains to avoid stagnant water.

- Color zoning: different colors to define areas (dispensing, corridors, waste routes) supports 5S and visual management.

- Validation/qualification link: installation records, material CoA, MSDS, curing times, and cleaning compatibility must be documented; any repairs are controlled via change control.

Common issues in inspections: cracks, peeling, poor coving, and flooring that reacts with disinfectants—each creates a contamination and cleaning risk.