Temperature mapping in pharma is a documented study used to demonstrate that storage areas such as warehouses, cold rooms and stability chambers maintain uniform, controlled temperatures under normal operating conditions. It is a critical GMP requirement, as temperature excursions can directly affect the potency, stability and safety of medicines.

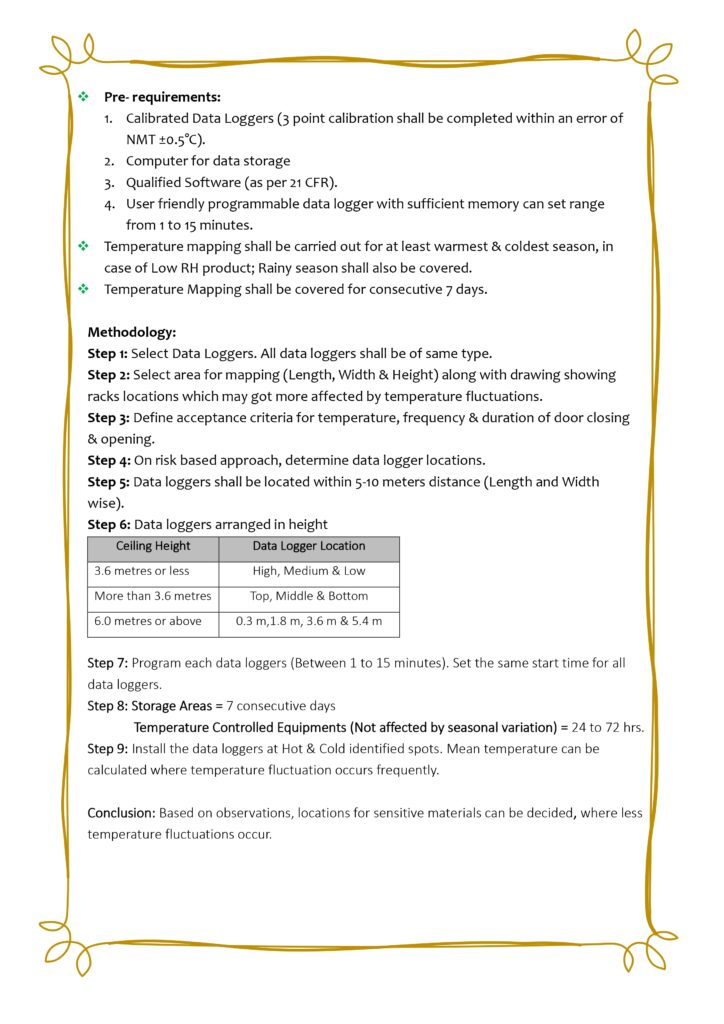

During a temperature mapping study, calibrated data loggers or sensors are strategically placed throughout the area to record temperature (and sometimes humidity) over a defined period. Locations are selected to represent worst-case positions: near doors, loading bays, ceilings, corners, air outlets, return ducts and densely loaded shelves. This helps identify hot and cold spots, temperature gradients and areas at risk during normal operations.

In warehouses, temperature mapping verifies that ambient or controlled room temperature zones remain within the specified range, even during door openings, vehicle loading, power fluctuations and seasonal changes. For cold rooms and walk-in refrigerators, mapping confirms that all product locations are kept within 2–8°C (or other defined limits), that fans and airflow patterns distribute cold air adequately, and that door-opening patterns do not compromise product safety.

In stability chambers and incubators, temperature mapping is closely linked to qualification and validation. The study demonstrates that set points and controls consistently deliver uniform conditions at each programmed temperature/humidity combination used for ICH stability studies or microbiological incubation. Any deviations, lag times or overshoots must be understood, assessed and controlled.

Typically, mapping is performed during initial qualification (empty and loaded conditions) and repeated at defined intervals or after significant changes such as relocation, major repairs, addition of equipment, or modifications in layout and insulation. Results are analysed statistically to verify compliance with acceptance criteria: mean temperature, maximum/minimum values, standard deviation and time spent outside limits.

A comprehensive report documents the methodology, calibration certificates, sensor layout diagrams, raw data, analysis, conclusions and recommended corrective actions. Based on the mapping, you define routine monitoring points, alarm set points and responses. In this way, temperature mapping provides evidence that pharmaceutical products are stored in a controlled, robust and compliant environment, reducing the risk of temperature-related product failures and regulatory findings.Thinking