Form-Fill-Seal (FFS) in pharma is an automated packaging process where a container is formed, then filled with product, and immediately sealed—all in one continuous, controlled operation. It is widely used for sterile liquids (BFS) and some non-sterile products because it minimizes human intervention, reduces contamination risk, and improves consistency.

Types used in pharma

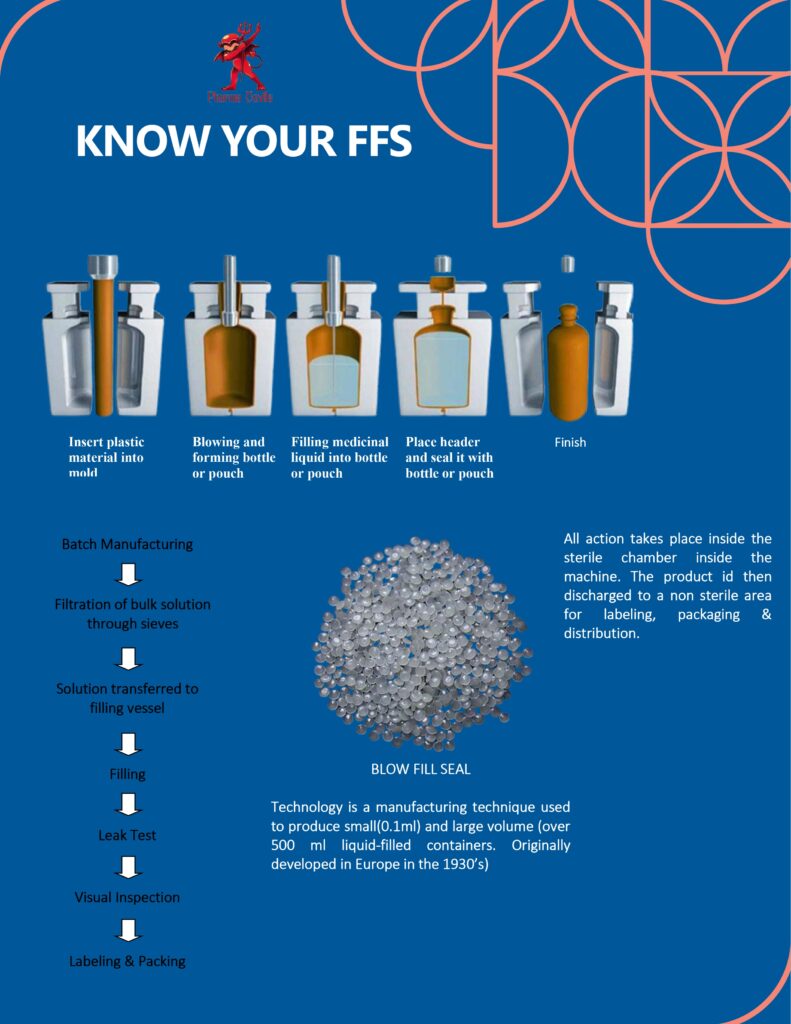

- BFS (Blow-Fill-Seal): Most common for sterile unit-dose products. A parison (molten polymer tube) is extruded, blown into a mold to form the container, filled aseptically, then sealed in the same machine cycle. Typical packs: ampoules, vials, bottles, IV containers.

- FFS sachet/strip (horizontal/vertical): Film is formed into pouches/sachets, filled, and sealed. Used for powders, granules, liquids (often non-sterile or low-risk sterile applications depending on design).

Basic process steps (BFS example)

- Polymer melting & extrusion (e.g., LDPE/PP)

- Container forming by blow molding inside the mold

- Filling through sterile filling nozzles (critical step)

- Sealing (top seal/closure formation)

- Cooling & ejection, then inspection and packing

Why it’s important

- Low contamination risk: minimal operator exposure

- High speed & repeatability: consistent fill volume and sealing quality

- Reduced handling: fewer transfers and open operations

- Good for unit-dose: improves patient safety and dosing accuracy

Critical Quality Attributes (CQA’s)

- Fill volume/weight accuracy

- Container integrity (CCI): seal strength, leak tightness

- Particulate control

- Sterility assurance (for BFS): aseptic conditions, environmental control

- Material quality: resin grade, extractables/leachables, compatibility

- Seal defects: pinholes, weak seals, deformation

Key controls (CPP’s)

- Polymer temperature, extrusion speed, mold temperature

- Aseptic zone airflow/HEPA integrity (BFS)

- Filling time, nozzle alignment, product temperature/viscosity

- Seal time/pressure/temperature

- Online monitoring: weight checks, vision inspection, leak testing

Validation & Compliance focus

- Process validation: forming, filling, sealing consistency

- Media fill / aseptic process simulation (for BFS sterile operations)

- Cleaning validation (product contact parts, nozzles, pathways)

- Environmental monitoring and operator interventions control

- Container-closure integrity testing and stability studies