A nitrogen system in a pharmaceutical facility provides a clean, dry, inert gas used to protect products, equipment, and processes from oxygen and moisture. “Know your nitrogen system” means understanding the full path—from source to point of use—so you can ensure quality, safety, and compliance.

1) Source and supply strategy

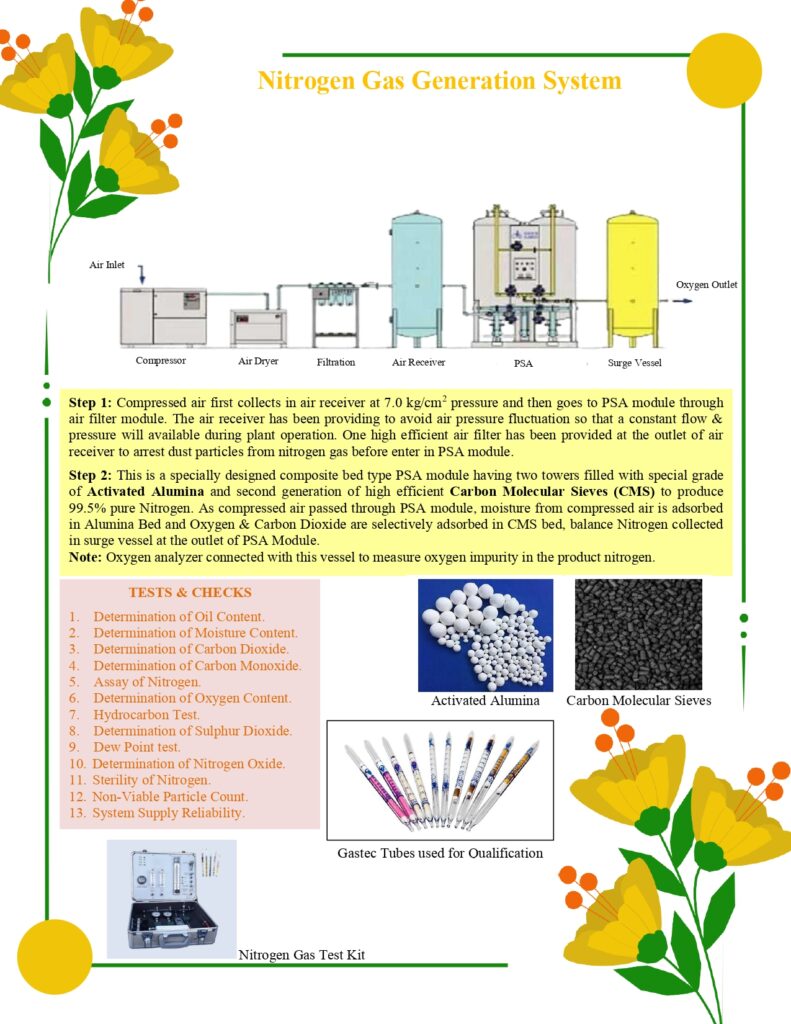

Nitrogen may come from liquid nitrogen (LN₂) tanks, on-site generation (PSA/membrane), or cylinders as backup. Know your primary source capacity, reserve/backup arrangements, and changeover procedure so critical operations never stop.

2) Purity and quality requirements

Different uses need different purity (e.g., inerting, purging, blanketing, packaging, instrument air crossover risks). Define specifications such as nitrogen purity (%), oxygen content (ppm), dew point (dryness), oil content, and particulate limits. Ensure filters/dryers are appropriate for the intended use and that you’re not over-specifying (wasting cost) or under-specifying (risking product).

3) Storage and distribution

Map the distribution network: vaporizers, buffer receivers, ring mains, pressure regulators, isolation valves, non-return valves, and point-of-use regulators. Confirm pressure setpoints, line sizing, pressure drop, and the most distant “worst-case” user.

4) Monitoring and alarms

Critical instruments include pressure gauges/transmitters, oxygen analyzers (where needed), dew point meters, and low-level alarms on LN₂ tanks or generator faults. Review alarm limits, escalation, and response time.

5) Risk and safety

Nitrogen is an asphyxiant. Identify confined spaces and low-lying areas, install oxygen deficiency monitors where required, ensure ventilation, signage, and permit-to-work controls.

6) Maintenance and compliance

Maintain a preventive plan for filters, dryers, valves, vaporizers, generators, and analyzers. Calibrate instruments, trend purity/dew point, document deviations, and keep SOPs, IQ/OQ/PQ (where applicable), and change control aligned with GMP expectations.

A well-understood nitrogen system reduces batch risk, downtime, and safety incidents—while keeping operations audit-ready.