A Pure Steam Generator (PSG) is a critical GMP utility used in pharma to produce high-purity steam for Sterilization-In-Place (SIP), autoclaves, sterile tank/jacket heating, and clean steam applications where product-contact risk exists. Unlike plant steam, pure steam is generated from purified water (PW) or Water for Injection (WFI) and must meet strict limits for chemical impurities, non-condensable gases (NCG), dryness fraction, and endotoxins (where applicable).

How it works

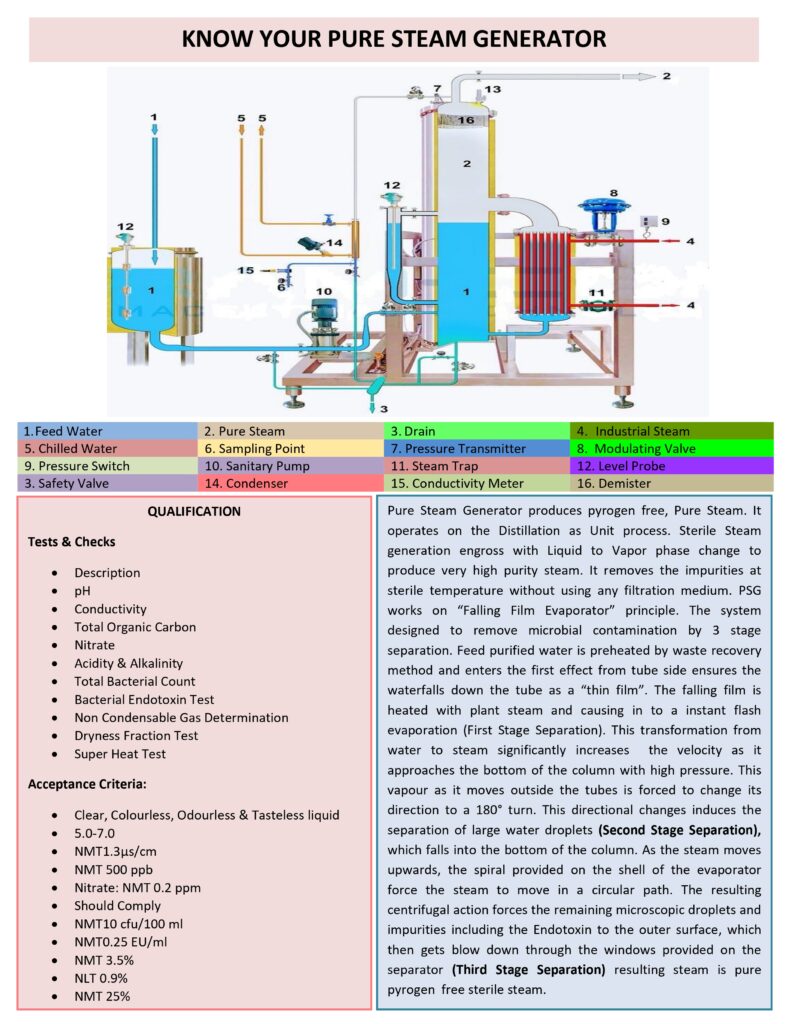

A typical PSG is a heat exchanger–based system: clean feed water enters and is vaporized using a heating medium (often plant steam). Proper design ensures no cross-contamination between heating steam and generated pure steam. Many systems use a vertical shell-and-tube with sanitary construction, hygienic welds, and drainable piping to prevent pooling.

Key components

- Feed water system: pump, preheater (optional), filters, conductivity monitoring

- Evaporator/Separator: produces steam and separates droplets to reduce carryover

- Clean steam outlet train: pressure control, separators, steam traps, sample points

- Controls & safety: PLC, alarms, PRVs, interlocks, blowdown control

Critical quality attributes

- Dryness fraction: wet steam can cause poor sterilization and condensate hammer

- Superheat (should be minimal): superheated steam sterilizes less effectively

- NCG: excess air/CO₂ reduces heat transfer and creates cold spots

- Endotoxin/pyrogen control: essential when steam contacts sterile surfaces

Qualification & monitoring

PSG requires DQ/IQ/OQ/PQ, periodic steam quality testing (dryness, NCG, superheat), and routine monitoring of feed water quality, conductivity, pressure, temperature, and blowdown. Preventive maintenance focuses on descaling, trap function, separator integrity, gasket condition, and calibration.

Common failures to watch

Carryover due to poor separation, incorrect slope/drainage, faulty traps, high NCG, scaling reducing capacity, and unstable pressure control—each can compromise SIP lethality and compliance.