Here’s a practical, end-to-end overview of a Purified Water (PW) system in pharma: pre-treatment → generation → storage → distribution—what each stage does, typical equipment, and key GMP controls.

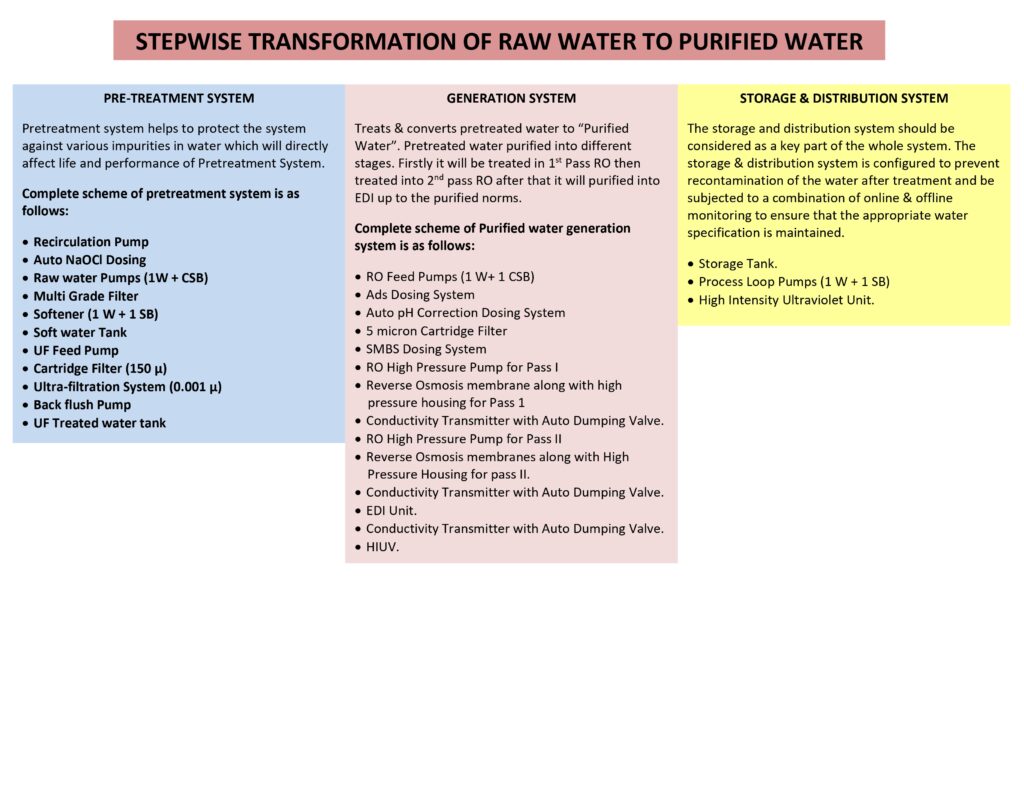

1) Pre-treatment (protect the RO/EDI and stabilize feed quality)

Purpose: reduce hardness, chlorine, suspended solids, organics, and fouling risks so the generation step is reliable.

Common train (typical order):

- Raw water tank / break tank (optional): buffers supply and isolates municipal pressure fluctuations.

- Multi-grade sand / media filter: removes turbidity and suspended solids.

- Activated carbon filter (ACF): removes free chlorine/chloramines and organics (protects RO membranes).

- Water softener (Na⁺ exchange): removes hardness (Ca/Mg) to prevent scaling.

- Chemical dosing (as needed):

- Antiscalant (if softener not used or in high scaling waters)

- SMBS (dechlorination, where carbon isn’t sufficient)

- pH adjustment (rare; depends on feed)

- Cartridge filter (5–1 µm): final particulate barrier before RO.

- Online instruments: pressure drop (ΔP) across filters, residual chlorine after ACF, flow, conductivity, SDI (optional).

GMP focus:

- Control carbon bed microbial growth (sanitization/steam/hot water where designed, defined changeout).

- Avoid “dead legs” and stagnant zones in pre-treatment piping.

- Trend ΔP and chlorine breakthrough to prevent RO damage.

2) Generation (produce PW to spec)

Purpose: remove dissolved salts/ions, organics, and microorganisms.

Typical generation options:

- Double-pass RO (2RO): strong, widely used baseline for PW.

- RO + EDI (electrodeionization): continuous polishing to low conductivity without chemical regeneration.

- UV (254 nm): reduces bioburden; often placed before storage or in loop.

- UV (185 nm) for TOC reduction: used to break down organics (often paired with 254 nm).

- Final membrane (UF/MF, optional): used where tighter microbial/endotoxin control is needed (more common in WFI systems).

Key controls:

- Online conductivity/resistivity (after RO/EDI and sometimes at multiple points)

- Flow, pressure, temperature

- RO performance: salt rejection, differential pressure, permeate conductivity trend

- Defined sanitization strategy for RO/EDI (hot water capable designs are preferred where feasible).

3) Storage (hold PW without letting it degrade)

Purpose: store PW hygienically and maintain quality between generation and use.

Typical storage design (sanitary):

- 316L SS tank, internal finish appropriate for pharma service

- Sloped bottom with full drain, minimal nozzles

- Spray ball for CIP / sanitization

- Hydrophobic sterilizing vent filter (0.2 µm) with integrity test program

- Level control, temperature monitoring (if heated loop), overflow/return arrangement

- Often designed for continuous recirculation to the distribution loop

Critical risks:

- Warm, stagnant water → biofilm formation.

- Poor vent filtration → microbial ingress.

- Long hold times → rising microbial counts/TOC.

4) Distribution (deliver PW to points of use, continuously controlled)

Purpose: keep water moving and sanitary all the way to user valves.

Typical loop features:

- Continuous recirculation loop (ring main), balanced returns

- Sanitary diaphragm valves, hygienic sample valves

- Point-of-use (POU) valves designed to minimize dead legs

- Velocity/turbulence sufficient to discourage biofilm (site-specific design)

- Heat sanitizable loop (hot PW) or chemical/ozone sanitization depending on philosophy

- Optional UV and final filter near critical POUs (used carefully—filters can become bioburden traps if not managed)

Instrumentation & monitoring:

- Online conductivity (often in return)

- TOC (online or periodic, depending on system criticality)

- Temperature (if hot loop)

- Routine sampling plan: incoming, generation outlet, tank, loop return, and representative POUs

- Microbial monitoring with alert/action limits and trending

Sanitization (make it a defined, repeatable program)

Common approaches:

- Hot water sanitization (robust, simple operations once designed)

- Ozone sanitization (effective at ambient temperature; needs ozone destruction before use)

- Chemical sanitization (e.g., peracetic acid/hydrogen peroxide blends) with validated rinse-out

Validation essentials (what auditors expect)

- Clear URS/DQ (intended use, required quality, capacity, materials)

- IQ/OQ/PQ with worst-case and seasonal feed variation considered

- Defined alert/action limits, deviation handling, and CAPA

- Strong trend review (conductivity, TOC, micro, sanitization records)

need to be elaborate about this complex system .

dear Whatsapp only