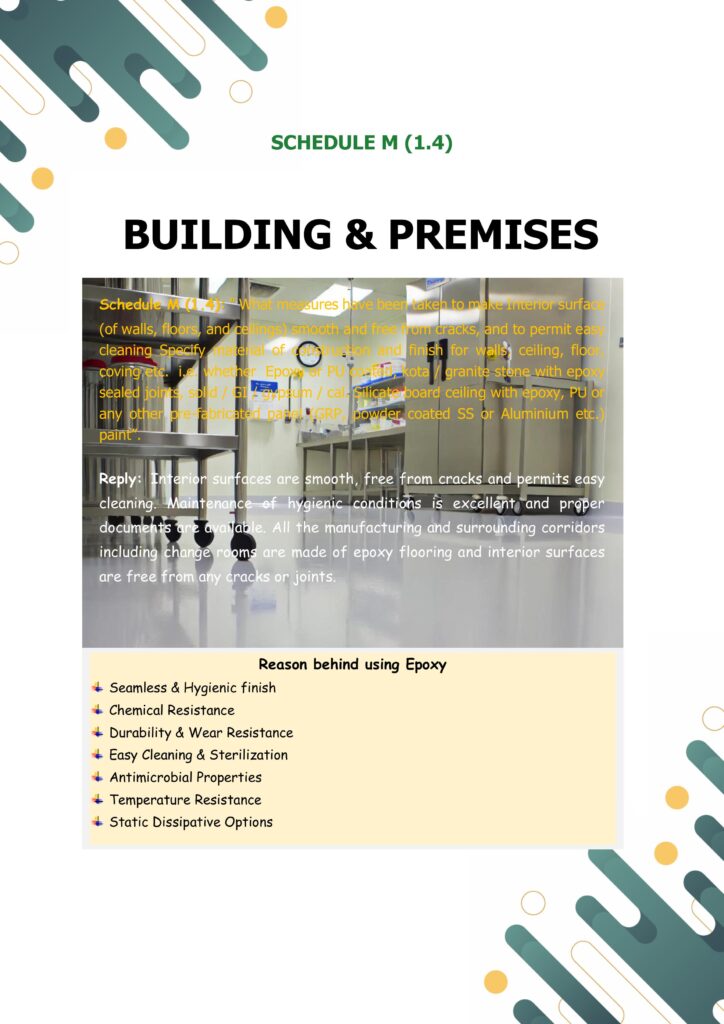

Risk Based Inspection (RBI) – Schedule M Point 1.4 (as captured in the CDSCO RBI checklist) checks what measures your site has taken to ensure interior surfaces—walls, floors, ceilings and coving—are smooth, free from cracks/open joints, and permit easy cleaning. The checklist specifically expects you to state the construction material and finish (e.g., epoxy/PU coating, kota/granite with epoxy-sealed joints, GI/gypsum/cal-silicate board ceiling, or prefabricated panels such as GRP/powder-coated SS/aluminium). CDSCO

Why this is “risk-based”

Interior surface condition directly influences:

- Contamination control: cracks, chipped plaster, flaking paint and open joints can harbor dust/microbes and are hard to sanitize.

- Cross-contamination control: porous or damaged surfaces can trap residues and spread particulates between campaigns/areas.

- Pest prevention: damaged surfaces and gaps support pest ingress and nesting.

Schedule M therefore requires premises to be designed/maintained so interior surfaces are smooth and crack-free, enabling effective cleaning/painting/disinfection, and also states walls/floors should be free from cracks/open joints to prevent dust accumulation and should not shed particles, with periodic cleaning/painting records maintained.

What inspectors typically verify

1) Physical condition (walk-through evidence)

- No visible cracks, peeling paint, powdering, damp patches, fungal growth

- Proper coving at floor–wall junctions; sealed penetrations (pipes, conduits)

- Ceilings intact (no open grids in critical zones unless justified)

2) “Material of construction” justification

- Floors: epoxy/PU or equivalent non-porous finish; joints sealed

- Walls: smooth, washable coating; impact-resistant where trolleys move

- Ceilings: sealed, cleanable panels; no particle shedding

3) System evidence

- Preventive maintenance program for repair of cracks/chips

- Cleaning SOPs + area cleaning records; periodic painting/repair logs

- Change control for any civil modifications affecting cleanability

Typical non-compliances: cracks in corridors/non-critical areas, unsealed joints, flaking paint, porous surfaces, missing repair records—because these are early indicators of loss of contamination control.