In risk-based inspection (RBI) aligned to Schedule M expectations for utilities, points 4.30–4.31 in the CDSCO RBI checklist target a high-impact risk source: compressed air (and other process gases) that contacts product or primary containers. Even when “invisible”, contaminated air can introduce particles, oil aerosols, moisture, microbes, or pyrogens, causing sterility failures, particulate contamination, corrosion, or stability issues—especially in sterile/aseptic operations and during drying, filtration assistance, container blowing, stopper/bottle handling, and line pneumatic functions.

4.30 – Qualification documents for compressed air (product/primary contact)

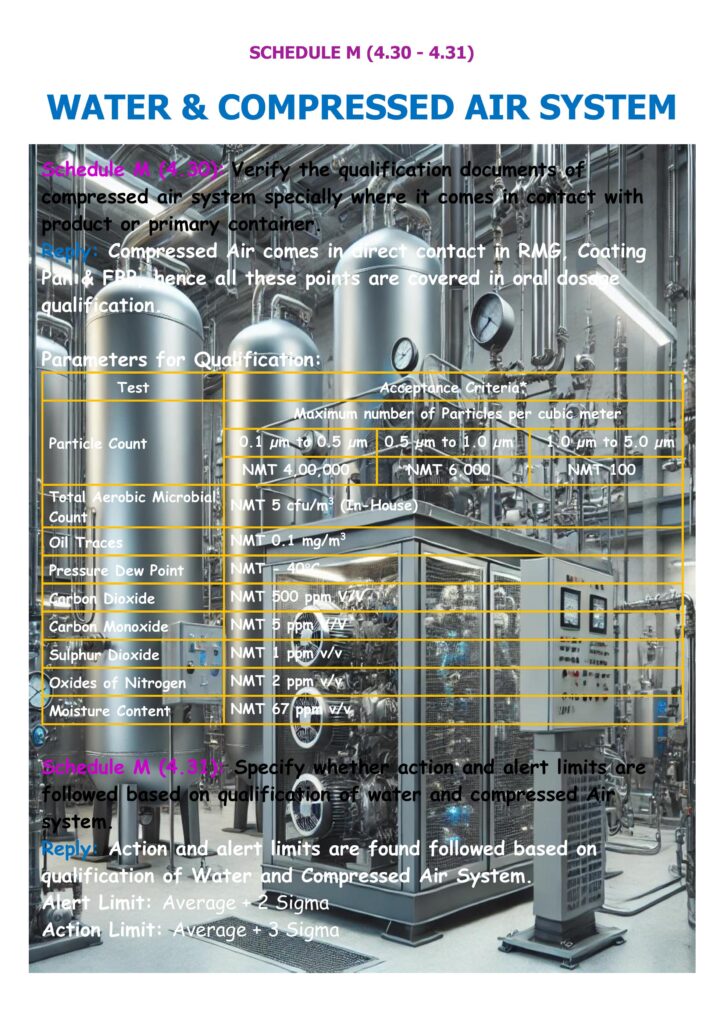

Inspectors verify that the compressed air system is qualified, specifically where it comes in contact with product or primary container. CDSCO

RBI focus is not only “do you have a compressor?”, but whether you have a lifecycle file proving the system is fit for intended use:

- Design basis/URS (required air quality at points of use: particles, oil, water, microbial where applicable).

- DQ/IQ/OQ/PQ evidence: material of construction, slope/drain points, receiver design, auto drains, condensate management, and instrument calibration.

- Filtration train (prefilters, coalescing, activated carbon if needed, sterile/point-of-use filters), filter integrity/leak tests and replacement frequency.

- Point-of-use sampling plan based on risk/worst case, including after maintenance and at routine frequency (moisture/dew point, oil content, particle counts, microbial if specified).

- Change control for compressor oil type, filters, dryers, distribution modifications, and major interventions.

4.31 – Alert/action limits followed (water + compressed air)

Inspectors check whether alert and action limits are established based on qualification and are being followed for water and compressed air systems. CDSCO

RBI expects: documented limits, trend charts, clear excursion response (immediate containment, impact/risk assessment on affected batches, investigation root cause, CAPA), and effectiveness checks. Strong systems show rapid detection (alarms), disciplined deviation handling, and evidence that repeated “near-limits” trigger preventive actions before failures occur.