Risk-Based Inspection (RBI) increases inspection depth where the potential patient risk is highest—and packaging/label controls are always high risk because mix-ups can lead to wrong medicine, wrong strength, wrong batch/expiry and rapid recalls. CDSCO

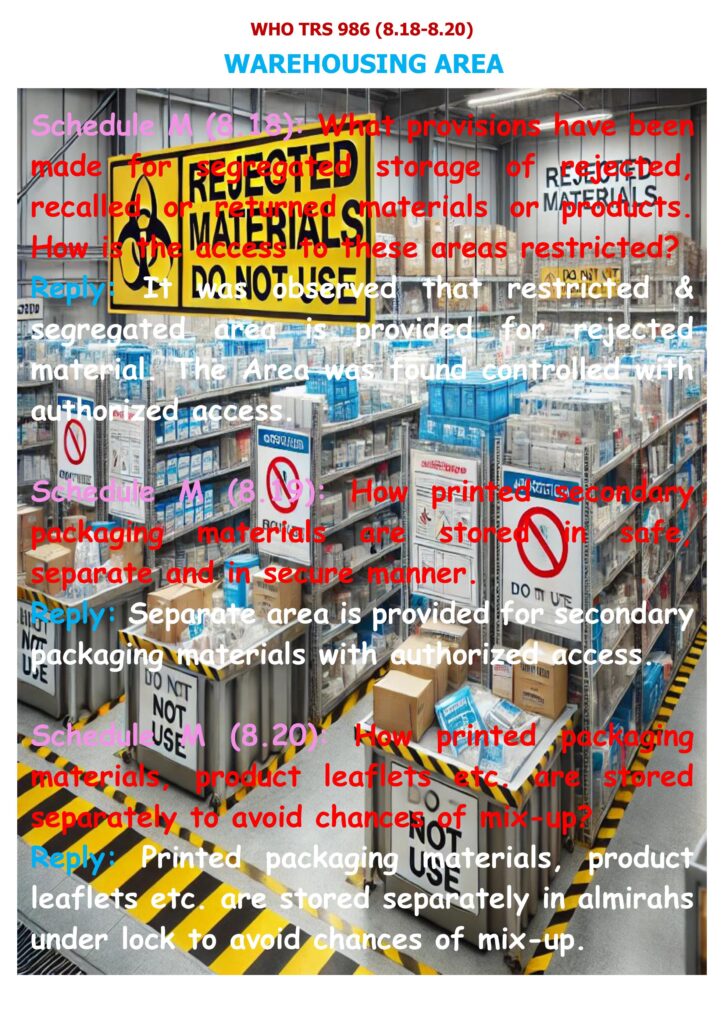

In the CDSCO RBI checklist, Schedule M points 8.18–8.20 focus on segregation and secure storage of (a) rejected/recalled/returned stock and (b) printed packaging materials, to prevent mix-ups and unauthorized use.

8.18: Segregated storage of rejected, recalled, returned materials/products

Inspectors check what provisions exist for segregated storage and how access is restricted. Practically, RBI verifies:

- Physical segregation (cages/rooms/racks) with clear labels: REJECTED / RETURNED / RECALLED / QUARANTINE.

- Access control (lock/key control, entry log, restricted roles in ERP).

- Status traceability: batch/lot, quantity, date, reason, disposition authority.

- Disposition workflow: QA/QC evaluation of returns, decision for re-test/rework (if allowed)/return-to-vendor/destruction, with documented impact assessment.

Because mis-handling here can reintroduce bad stock into saleable inventory, repeated gaps push RBI to expand into recall system, complaints, batch release, and inventory controls.

8.19: Secure storage of printed secondary packaging materials

The checklist asks how printed secondary packaging is stored “safe, separate and secure.” RBI expects:

- Dedicated locked storage with controlled issuance (two-person verification for critical prints).

- Reconciliation of issued vs used vs returned vs destroyed (no “loose” labels/cartons).

- Obsolete artwork control (quarantine and destruction of superseded prints; change-control linkage).

8.20: Separate storage of printed packaging materials and leaflets to avoid mix-ups

Inspectors verify how printed materials and product leaflets are stored separately to avoid mix-ups. Typical good practices:

- Segregation by product/strength/market with clear bin locations and color coding.

- FEFO/expiry control for pre-printed materials where applicable.

- Controlled issue to line + return controls to prevent accidental reuse.

Common RBI observations: shared cupboards, poor reconciliation, unrestricted access, mixed leaflets/artworks, and “status not clear”—all treated as high-risk due to direct patient impact.