In a risk-based inspection (RBI), Schedule M points 8.33–8.35 are checked as dispensing and material-control safeguards because failures here can directly cause mix-ups, cross-contamination, and safety/security breaches (especially with hazardous and controlled substances).

8.33 — Dispensed materials kept together and conspicuously labelled

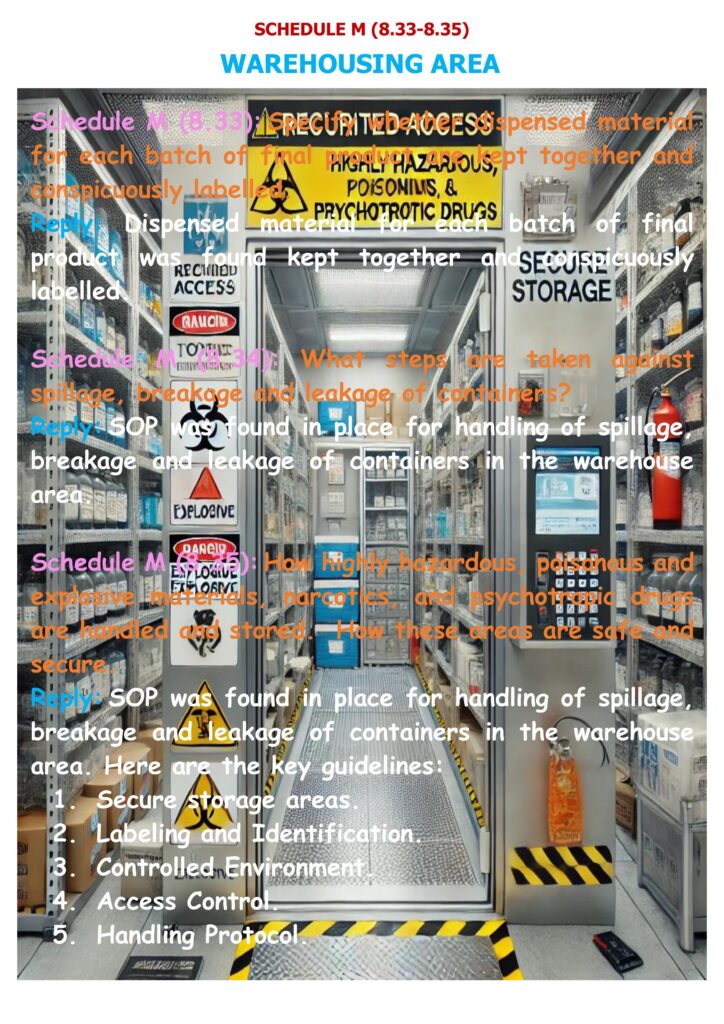

Inspectors verify that dispensed materials for each batch are kept together and clearly labelled (batch/product/strength/status/quantity/date/dispensed-by/checked-by), so materials cannot drift into another batch or be mistakenly reused. RBI emphasis is on real-life controls: dedicated batch staging (physically segregated), closed containers, tamper-evident identification, and a reconciliation trail from weighing sheet to container ID to issuance. The checklist specifically asks whether dispensed materials for each batch are kept together and conspicuously labelled. CDSCO

8.34 — Steps against spillage, breakage and leakage of containers

Inspectors review the SOP and practical readiness for spillage/breakage/leakage: spill kits, containment materials, PPE, safe clean-up steps, area isolation, waste disposal, and documented incident reporting with impact assessment (material loss, contamination risk, line clearance). RBI also checks whether warehouse/dispensing staff are trained and whether repeated incidents trigger CAPA. The checklist asks what steps are taken against spillage, breakage and leakage of containers (and expects an SOP). CDSCO

8.35 — Handling and secure storage of hazardous/poisonous/explosive materials; narcotics/psychotropics

Inspectors verify segregated storage with safety features: dedicated rooms/cabinets, ventilation as needed, compatible storage (e.g., flammables), restricted access, and security controls for narcotics/psychotropics (locks, controlled keys/access logs, dual verification, stock reconciliation, dispensing authorization). The checklist explicitly asks how such materials are handled and stored and how areas are safe and secure. CDSCO

Common RBI red flags: loose/unlabelled dispensed containers, shared staging areas between batches, spill events handled informally, and inadequate segregation/security for controlled or hazardous materials.