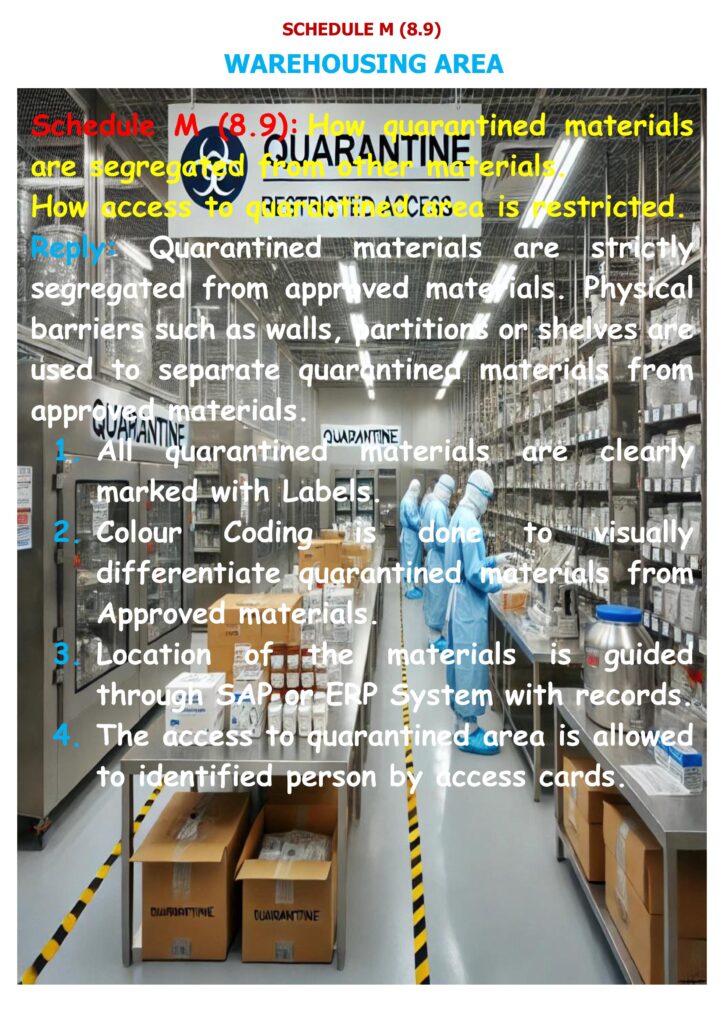

Risk-Based Inspection (RBI) – Schedule M Point 8.9 (Quarantine segregation & restricted access)

What 8.9 checks (RBI checklist intent): Inspectors verify how quarantined materials are segregated from other materials and how access to the quarantined area is restricted. CDSCO

Why 8.9 is high-risk in RBI

Quarantine is the “hold” status for incoming or unapproved materials. If quarantine controls are weak, the site can accidentally dispense untested/failed materials, causing batch quality failures, contamination, mix-ups, and potential recalls. RBI therefore treats quarantine as a core material-status control that predicts overall GMP discipline.

Regulatory/GMP basis behind the checkpoint

Schedule M requires that all incoming materials are quarantined immediately after receipt/processing and stored to permit segregation and stock rotation, with clear status labelling such as quarantine / under test / released / rejected and separate areas for under-test, approved and rejected materials.

WHO GMP is explicit that when quarantine status is ensured by storage in separate areas, these areas must be clearly marked and their access restricted to authorized personnel, and any electronic/alternative system must provide equivalent security.

What RBI inspectors verify (practical evidence)

- Physical or system segregation

- Dedicated quarantine zone (caged/racked/room) with signage, floor marking, and clear boundaries.

- No mixed pallets: quarantine materials are not stored on the same rack face with “released” stock.

- Access restriction controls (the key 8.9 focus)

- Restricted keys/badges, lockable cages/rooms, access logs/CCTV (as applicable).

- Only authorized warehouse/QA/QC personnel can move status or issue materials.

- Status labelling and traceability

- Each container shows material name/code, supplier batch/lot, internal control number, and status (quarantine/released/rejected), with dates (expiry/retest where applicable).

- Workflow discipline

- Proof that no material is issued before QC disposition (ERP blocks + physical controls).

- Handling of damaged containers: recorded and segregated until disposition.

Common RBI observations (typical gaps)

Unrestricted “quarantine corners,” shared racks, handwritten/unclear status labels, ERP status changed without QA control, and movement/issuance without traceable authorization—each is treated as a mix-up risk and can expand RBI into dispensing controls and deviation/CAPA effectiveness.