In WHO TRS 986 (Annex 2), 10.1–10.5 define the GMP training system inspectors expect to see working in practice—not just a “training file”. Under a risk-based inspection (RBI), regulators prioritize inspection depth and sampling based on public-health risk and compliance signals, so weak training control becomes a “risk multiplier” (more interviews, more record sampling, broader system review). U.S. Food and Drug Administration+1

What TRS 986 requires (10.1–10.5)

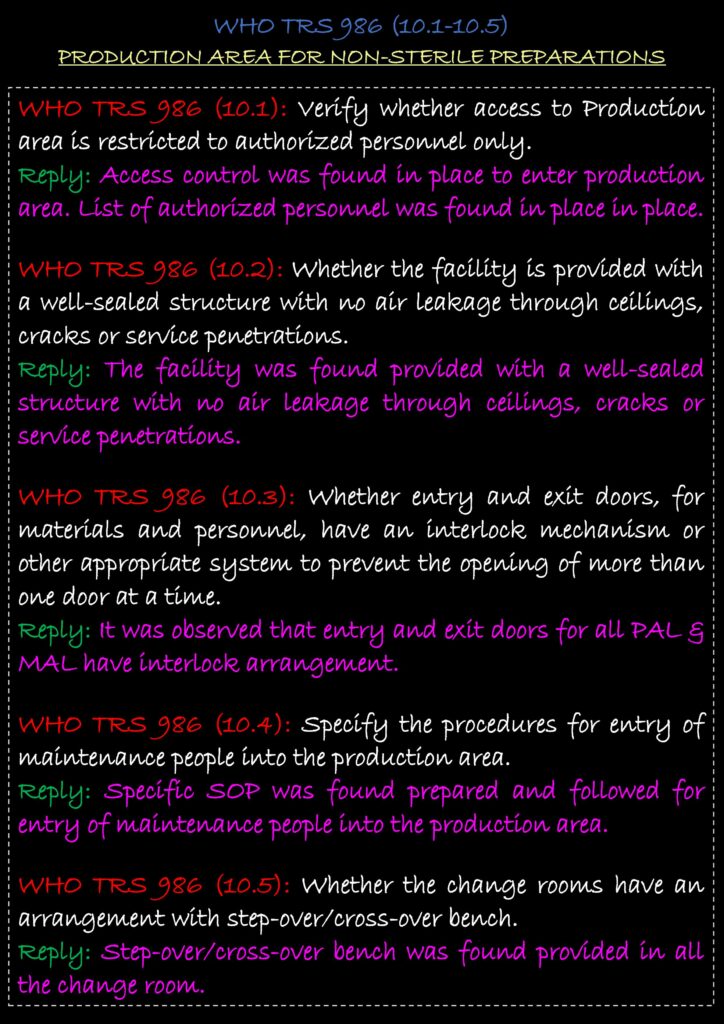

- 10.1 Written training program: The manufacturer must provide training per a written program for all personnel entering manufacturing or QC areas (including technical, maintenance, cleaning staff) and others as required.

- 10.2 Induction + job training + continuous training: New recruits must receive GMP theory/practice plus role-specific training; continuing training is required and its practical effectiveness periodically assessed. Approved programs must be available and training records kept.

- 10.3 High-risk area training: Personnel in contamination-hazard areas (e.g., clean areas, highly active/toxic/infectious/sensitizing materials) need specific training.

- 10.4 QA mindset: Training must fully discuss the concept of QA and measures that support understanding and implementation.

- 10.5 Visitors/untrained personnel: They should preferably not enter production/QC; if unavoidable, provide advance information (especially hygiene), required protective clothing, and close supervision.

How RBI checks compliance (what inspectors look for)

- Training needs analysis (TNA) & matrix: role vs SOP/process mapping, including contractors (maintenance/cleaning) and QC analysts; risk-ranked for aseptic, potent products, data-critical tasks.

- Effectiveness evidence: not only signatures—proof via assessments, observations, error rates, OOS/OOT linkage, gowning qualification, aseptic practices checks, and retraining after deviations/changes.

- Shop-floor interviews: operators explain critical steps, ALCOA+ behaviors, contamination controls, and what to do on abnormal events (spills, excursions, mix-up risk).

- Visitor control: escort logs, induction briefing, hygiene instructions, and PPE controls aligned to area risk.

Common RBI findings include “training done but not effective,” missing training for maintenance/cleaning, weak high-risk-area qualification, and poor control of visitors—each increasing the inspection scope and follow-up intensity.