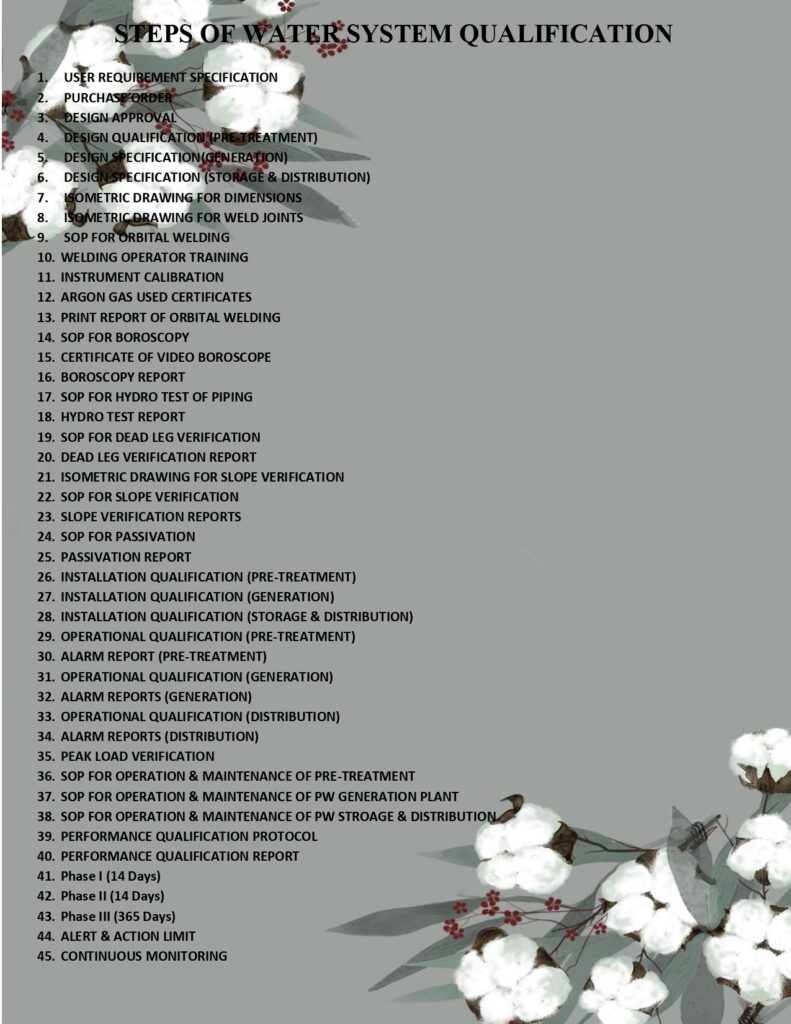

Steps of Water System Qualification in Pharma

Qualification of a pharmaceutical water system (Purified Water / WFI) is done in a structured, documented sequence to prove that the system is designed, installed, operated, and performs consistently as per GMP.

1. URS, Design & Risk Assessment (Pre-Qualification)

- Prepare User Requirement Specification (URS) – capacity, quality (PW/WFI), temperature, storage volume, loops, sanitization method, regulatory standards (IP/BP/USP/EP).

- Do a design review – P&IDs, material of construction (SS 316L), slopes, dead-leg criteria, velocities, drainability, vent filters, instrumentation.

- Perform a risk assessment (e.g., 6M, FMEA) to identify critical parameters: temperature, flow, sanitization frequency, sampling points, biofilm risk, etc.

- Approve all drawings and technical specs before fabrication.

2. Installation Qualification (IQ)

Objective: Verify that the system is installed as per approved design and manufacturer’s recommendation.

Typical IQ activities:

- Check equipment and components against approved BOM and P&IDs.

- Verify material of construction, surface finish, gaskets, valves, weld logs, slopes, and drain points.

- Verify proper installation of tanks, heat exchangers, pumps, distribution lines, filters, instruments.

- Check instrument calibration (conductivity, TOC, temperature, pressure sensors).

- Confirm tag numbers, labels, and flow direction arrows.

- Compile IQ report with deviations and resolutions.

3. Operational Qualification (OQ)

Objective: Demonstrate that the system operates as intended over the defined operating ranges.

Typical OQ activities:

- Test start-up, shutdown, normal, and worst-case operations.

- Challenge control logic: interlocks, alarms, trips, set points (temperature, conductivity, level, pressure).

- Verify sanitization cycles (hot water/steam/chemical): parameters, time, temperature, sequence.

- Verify system drainability and dead-leg flushing.

- Conduct short-term trial runs and document trend data (temperature, conductivity, TOC where applicable).

- Prepare and approve OQ report.

4. Performance Qualification (PQ) – Phase 1, 2 & 3

PQ proves consistent performance over time under routine conditions. Usually divided into 3 phases.

Phase 1 – Intensive Monitoring (Start-Up)

- Duration: typically 2–4 weeks (as per site procedure).

- Run the system continuously as per routine SOPs.

- Very frequent sampling (e.g., daily from all key points: generation, tank, return loop, user points).

- Test for chemical, microbiological, TOC, conductivity, endotoxin (for WFI).

- Adjust parameters, sanitization frequency, and procedures based on data.

- Goal: stabilize operation and identify any initial issues.

Phase 2 – Routine Operation with Monitoring

- Duration: usually 2–4 weeks.

- Operate the system by trained users under finalized SOPs (operation, cleaning, sanitization, sampling).

- Continue frequent sampling, but pattern may be slightly optimized.

- Demonstrate that the system remains under control without major intervention.

Phase 3 – Long-Term Performance

- Duration: typically 3–12 months (as per company validation policy).

- Sampling as per routine monitoring plan (e.g., weekly from user points, daily from critical points).

- Show consistent compliance with specifications across seasons, load variations, and normal maintenance.

- Final PQ summary report concludes suitability of the water system.

5. Final Documentation, Handover & Ongoing Control

- Compile VMP, URS, DQ, IQ, OQ, PQ reports, trend charts, deviations and CAPA.

- Formally approve the system for GMP use.

- Implement ongoing routine monitoring, periodic sanitization, trending of data, and requalification (e.g., annually or after major changes).

Hello

How are You?

Hope you fine

Could You Pls Provide me the price of this documents package price

waiting your replay

THANK YOU

LEAVE YOUR MOBILE NUMBER