Purified Water (PW) system qualification in pharma is the documented proof that the PW system is designed, installed, operated, and performs consistently to deliver water meeting your defined chemical and microbiological requirements at all points of use—throughout routine operation.

1) Define requirements and design intent (URS + DQ)

- URS (User Requirement Specification): Purified Water grade, intended uses (manufacturing, equipment washing, CIP make-up), daily demand, peak flow, loop temperature (hot/ambient), sanitization method (hot water/ozone/chemical), storage philosophy, materials of construction (typically SS316L sanitary), and monitoring needs.

- DQ (Design Qualification): verify design meets URS and GMP principles:

- Continuous recirculation loop, minimal dead legs, sanitary slopes/drainability

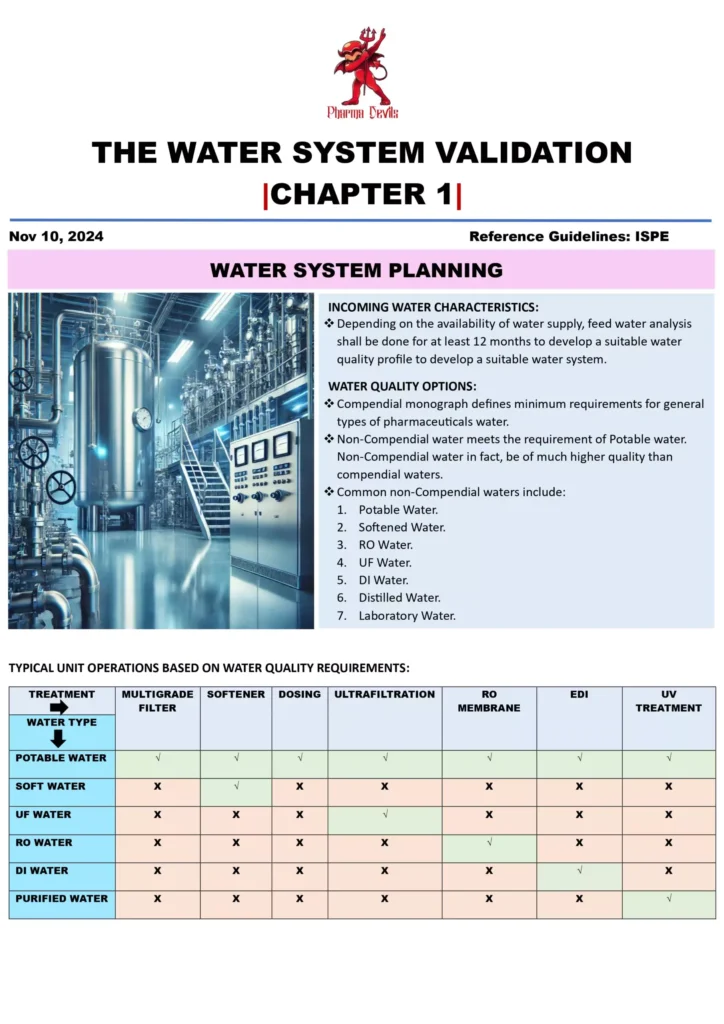

- Correct selection of purification steps (e.g., pretreatment → RO → EDI/mixed bed → UV/UF if used)

- Instrumentation strategy and alarm setpoints

- Sampling point selection (worst-case: tank, return, end-of-loop, low-use POUs)

2) Installation Qualification (IQ)

Document that the system is built as designed:

- Equipment IDs, P&IDs, piping isometrics, welding records/boroscope, surface finish/passivation

- Material certificates (MTC), gasket specs, filter/UV/RO/EDI details

- Calibration status of instruments (conductivity, TOC, temperature, flow, pressure)

- Utilities verification (feed water, power, drain), software/BMS configuration (if applicable)

3) Operational Qualification (OQ)

Prove the system operates correctly across operating ranges:

- Start-up/shutdown, recirculation flow/velocity, temperature control

- RO performance (rejection), EDI/mixed-bed function, UV intensity, vent filter integrity (where applicable)

- Alarm/interlock testing, instrument accuracy checks

- Sanitization cycle verification (time/temperature or ozone/chemical concentration/contact time) and recovery

4) Performance Qualification (PQ)

Demonstrate consistent water quality under routine conditions.

Typical PQ elements:

- Duration: commonly several weeks to cover variability (and ideally different operating patterns).

- Sampling plan: multiple points (tank, return, end-of-loop, representative + worst-case POUs).

- Tests: conductivity/resistivity, TOC, microbial counts; add specific ions/endotoxin if your risk assessment requires.

- Operational states: normal production usage, low-use periods, post-sanitization, and after maintenance events.

- Data review: trending, alert/action limits, investigation procedure for excursions.

5) Ongoing control (continued verification)

After qualification, maintain a state of control via:

- Online monitoring (conductivity/TOC where installed), routine microbiological sampling plan

- Scheduled sanitization, preventive maintenance, filter changes, calibration program

- Periodic review (trends, excursions, seasonal effects)

- Requalification triggers: major repairs, loop extension, sanitization change, persistent adverse trends, new POUs, change in usage/limits.