Understanding Warehouse in Pharma

A pharmaceutical warehouse is much more than a storage space. It is a GMP-controlled area where medicines, raw materials, packaging components, and intermediates are received, stored, protected, and issued in a way that preserves their quality, safety, and traceability.

1. Role of the Warehouse in Pharma

The warehouse links suppliers, production, quality, and distribution. Its main functions are:

- Receipt and verification of incoming materials

- Quarantine, sampling, and release by Quality Unit

- Controlled storage under defined environmental conditions (e.g. 2–8°C, 15–25°C)

- Issuance of materials to production as per FIFO/FEFO

- Storage of finished goods prior to dispatch

- Documentation and traceability of every movement and status change

Any failure at warehouse level can lead to mix-ups, cross-contamination, degradation, or mislabeling, directly impacting patient safety and regulatory compliance.

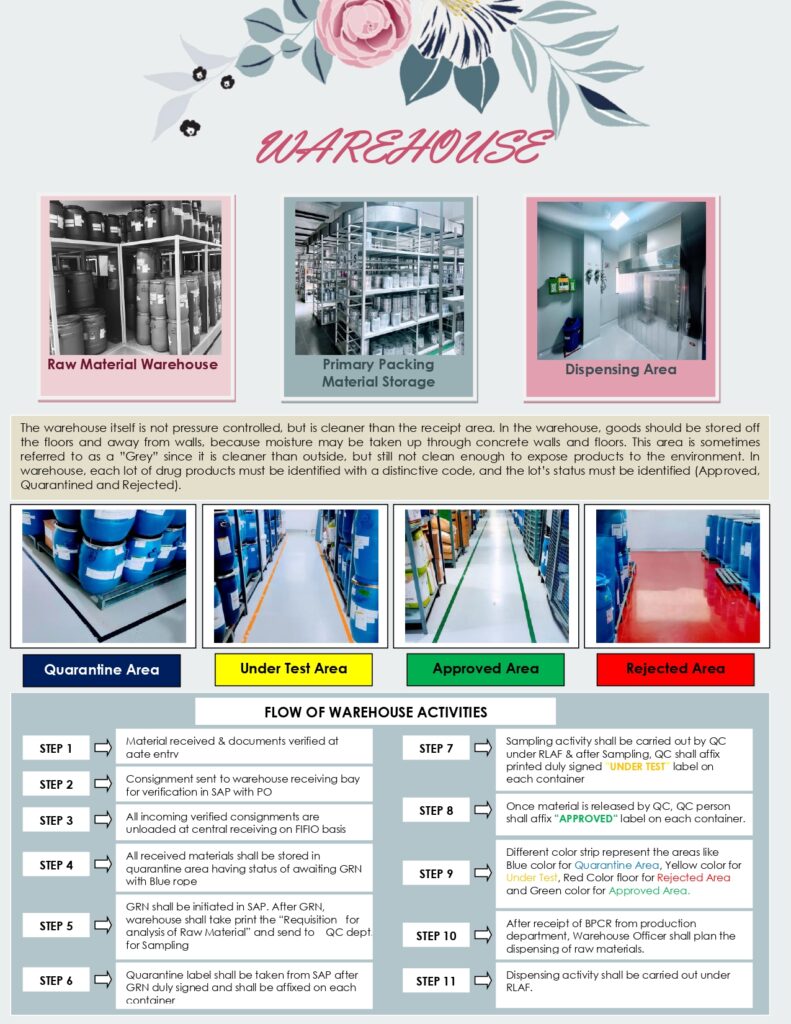

2. Types of Areas in a Pharma Warehouse

A typical pharmaceutical warehouse is divided into clearly defined, segregated zones:

- Material Receipt Area – unloading, preliminary checks, and identification

- Quarantine Area – materials kept “On Hold” until QC/QA release

- Approved / Released Area – only materials passed by QA are stored here

- Rejected / To Be Returned Area – physically segregated and clearly labeled

- Cold Room / Refrigerated Storage – for temperature-sensitive products

- Controlled Drugs / High-Value Area – with restricted access and extra security

- Dispensing / Issuance Area – line clearance, weighing, and issuing to shop floor

Clear material flow (unidirectional) and personnel movement control reduce the risk of mix-ups and contamination.

3. GMP and GDP Requirements

Warehouse operations in pharma must comply with GMP (Good Manufacturing Practices) and GDP (Good Distribution Practices). Key expectations include:

- Clean, dry, pest-free, and structurally sound facility

- Qualified temperature and, where needed, humidity control

- Continuous monitoring with alarms and periodic mapping

- Status labeling (Quarantine / Approved / Rejected / Returned / Under Test)

- Use of Validated Computerized Systems for inventory (ERP/WMS)

- SOP-driven activities for receiving, sampling, storage, and dispatch

- Full traceability and documentation for all materials and lots

4. Material and Inventory Control

To maintain control and avoid mix-ups, warehouses typically implement:

- Unique identification and coding (GRN, material code, batch/lot number)

- FIFO/FEFO (First In First Out / First Expiry First Out)

- Segregation by product, strength, and dosage form

- Regular stock reconciliation and investigation of discrepancies

- Controlled returns, recalls, and destruction procedures

5. Common Risks and How Warehousing Prevents Them

A well-designed warehouse helps mitigate risks like:

- Degradation due to temperature/humidity excursions

- Mix-ups of similar packs or strengths

- Cross-contamination from poor segregation or housekeeping

- Theft or diversion of high-value or controlled drugs

- Data gaps from poor documentation or manual errors

By enforcing good storage practices, robust documentation, and trained staff, the warehouse becomes a critical quality gate rather than a passive storage area.