Benzyl alcohol (BA) is used in injectable products mainly as an antimicrobial preservative (especially in multi-dose containers) and sometimes as a co-solvent to help dissolve an API. Here’s what matters most when you’re considering it in an injectable formulation.

Where it’s used (and typical levels you’ll see)

- Multi-dose diluents/flushes (classic example): Bacteriostatic Water for Injection contains 0.9% BA (9 mg/mL) (some presentations list 1.1% / 11 mg/mL) and is packaged as a multi-dose container. DailyMed

- BA is generally chosen when you need microbial control after multiple punctures/withdrawals (it’s not a substitute for sterility assurance).

The biggest safety constraint: neonates and very young children

BA exposure has been linked to serious and fatal reactions in neonates, including “gasping syndrome.”

- FDA safety communications and labeling repeatedly warn against using BA-containing flush solutions/diluents in newborns.

- EMA’s Q&A on BA notes IV exposure in the 100–200 mg/kg/day range has been linked to gasping syndrome in pre-term infants, and advises not using BA in neonates unless strictly necessary. European Medicines Agency (EMA)+1

- EU excipient labeling guidance also includes cautionary wording for young children (<3 years) (e.g., “do not use for more than a week…”), reflecting accumulation risk. European Medicines Agency (EMA)

Practical takeaway: If your product could be used in neonates/infants, regulators often expect a preservative-free alternative or a very strong justification + prominent warnings.

What regulators/compendia expect from a development & QC standpoint

If Benzyl Alcohol is used as an antimicrobial preservative in an injectable:

- You should demonstrate preservative effectiveness (challenge testing) in the final container (or representative final system) and confirm it holds through shelf-life. EMA’s excipient dossier guidance explicitly expects antimicrobial efficacy assessment during development and at end of shelf-life. European Medicines Agency (EMA)

- Compendial preservative efficacy approaches are described in Ph. Eur. 5.1.3 (challenge, timed sampling, microbial counts, acceptance criteria by product category). DrugFuture

- Labeling should clearly declare the preservative and include age-related warnings where applicable (EU excipient guideline provides the template language). European Medicines Agency (EMA)

Formulation realities (things that commonly make or break BA use)

- Container/closure & in-use period: BA is mainly about in-use microbial risk in multi-dose presentations. Your closure puncture performance + in-use study design matters.

- pH/compatibility: BA efficacy and API compatibility can be pH-sensitive. (Example: bacteriostatic water with BA is typically around pH ~5.7, with a stated range 4.5–7.0). DailyMed

- Stability: you’ll want to track BA assay and relevant degradants/impurities (and ensure sterilization process doesn’t change BA content beyond specs).

- Patient tolerability: BA can contribute to irritation/hemolysis/pain on injection depending on route, concentration, and product matrix—so you’ll often need clinical/clinical-bridging justification for the chosen level.

Quick calculation you should always do (for labeling & pediatric risk)

Benzyl Alcohol exposure (mg/day) = BA concentration (mg/mL) × dose volume (mL) × doses/day

Example: if BA is 9 mg/mL (0.9%) and dose is 2 mL once daily, exposure = 18 mg/day.

For pediatric/neonate discussions, convert to mg/kg/day:

mg/kg/day = (mg/day) ÷ body weight (kg)

Practical “use / don’t use” rule of thumb

Use Benzyl Alcohol when:

- You truly need a multi-dose injectable presentation, and

- Target population is not neonates, and

- You can pass preservative effectiveness + stability + in-use studies, and

- Labeling/warnings are acceptable for your markets.

Avoid Benzyl Alcohol (or default to preservative-free) when:

- Product is for neonates / very young infants, or

- Route/use leads to high cumulative exposure, or

- You can reasonably make a single-dose presentation instead.

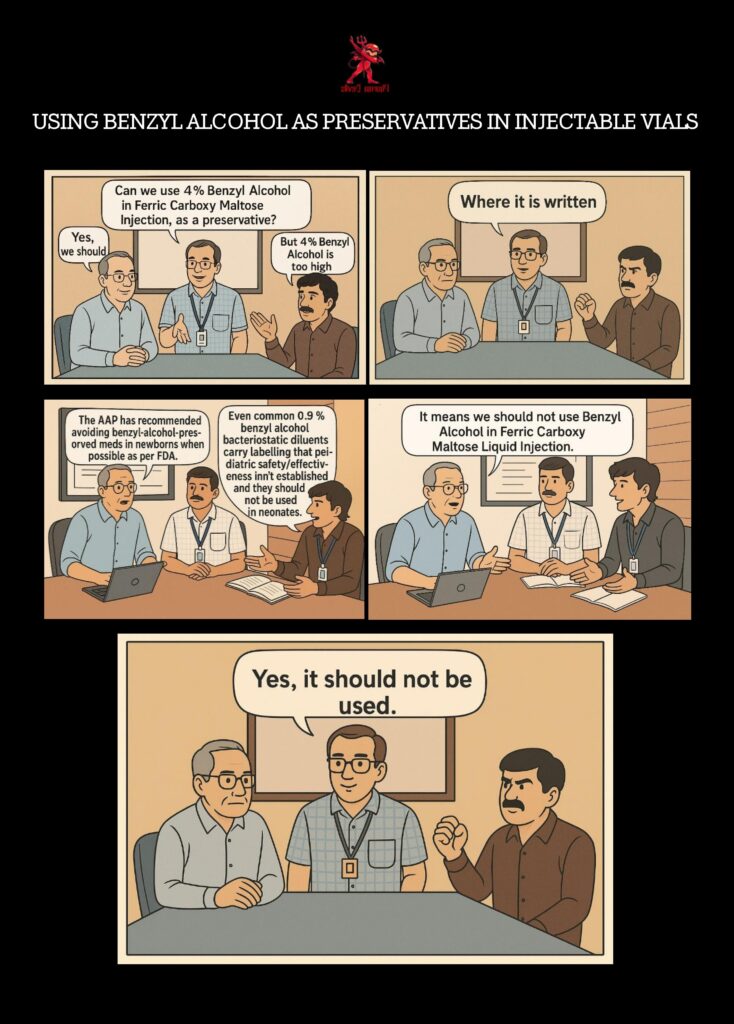

In ferric carboxy maltose liquid injection

For ferric carboxymaltose (FCM) liquid injection, the marketed/approved products are typically preservative-free and do not contain benzyl alcohol.

- Injectafer (US label): lists inactive ingredients = water for injection, with sodium hydroxide / hydrochloric acid only for pH adjustment (pH 5.0–7.0). No benzyl alcohol is listed. FDA Access Data+1

- Ferinject (UK SmPC): excipients are sodium hydroxide, hydrochloric acid, and water for injections—again no benzyl alcohol. Medicines.org.uk+1

What this means practically

- You should not add benzyl alcohol to FCM injection to “make it multi-dose.” That would create a new formulation and would trigger full justification/work (preservative efficacy, compatibility, stability, safety/labeling—especially pediatric warnings).

- FCM vials are generally treated as single-use; after first puncture/opening, microbiological safety is a key concern because there’s no preservative. (The SmPC also emphasizes use under controlled aseptic conditions and provides in-use limits.) Medicines.org.uk

In India, the common Ferric Carboxymaltose (FCM) 50 mg/mL IV injections are typically preservative-free and do not list benzyl alcohol in their composition.

Examples (India market):

- Orofer FCM 1K (Emcure) pack composition panel shows: Ferric carboxymaltose (equivalent to elemental iron 50 mg/mL) + Water for Injections IP q.s. (no benzyl alcohol listed). Imimg

- Orofer FCM (leaflet scan) similarly shows Water for Injections IP q.s. in the “Each mL contains…” section (no benzyl alcohol listed). Imimg

- MSN Labs “For use in India only” prescribing information lists water for injection IP q.s. as the vehicle (no benzyl alcohol listed). msnlabs.com+1

This aligns with international labeling too (e.g., US Injectafer lists only water for injection and acid/base for pH adjustment, not benzyl alcohol). FDA Access Data

So can you use benzyl alcohol in FCM injection?

Not in the standard/reference formulations. Adding benzyl alcohol would make it a different formulation (and usually a different presentation intent, like multi-dose), so you’d need full justification: compatibility/stability, extractables/leachables impact, preservative effectiveness testing, safety/labeling (including pediatric cautions), etc.

Practical handling point (hospital/pharmacy)

Because these are generally single-dose, preservative-free vials, once opened/punctured they should be handled as single-use under aseptic conditions (don’t “save the remainder” like a preserved multi-dose vial).