A pharma warehouse is a GMP/GDP-controlled storage and distribution area that protects raw materials, packaging materials, intermediates, and finished products so they remain identity-preserved, traceable, and within specification until use or dispatch. Warehousing is critical because poor storage can cause mix-ups, contamination, expiry failures, and temperature/humidity damage, directly impacting patient safety.

Key warehouse zones and controls

Pharma warehouses are typically divided into clearly marked areas: receiving, quarantine, sampling, released/approved, rejected, returned, recalled, and dispatch. Each status must be unmistakable using physical segregation (cages/rooms/racks), labels, and ERP status blocks. Access is restricted so only authorized personnel can move materials between statuses.

Environmental control

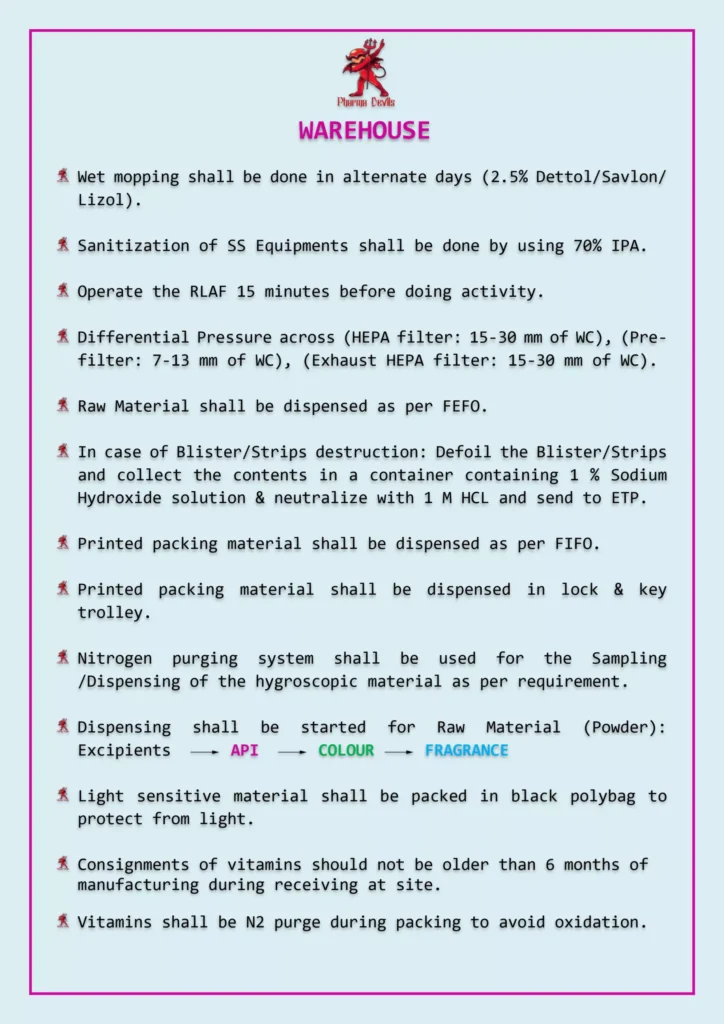

Warehouses must maintain suitable temperature and humidity for stored items. Cold rooms/freezers support refrigerated products and stability-sensitive materials. Temperature mapping, calibrated sensors, alarm systems, excursion handling, and pest control are essential. Cleanliness and good housekeeping prevent dust build-up and pest attraction.

Material handling and traceability

Incoming materials are checked against purchase orders and supplier documents, then placed in quarantine until QC disposition. Materials are stored on racks/pallets/platforms (not directly on floors), with clear location IDs. Issuance follows FIFO/FEFO (depending on expiry/retest). Every movement is recorded to maintain traceability from receipt → sampling → testing → release → dispensing/packing.

Sampling and security

Sampling of raw and packaging materials should occur in a controlled sampling area (often with a reverse LAF/downflow booth) to prevent contamination and mix-ups. Printed packaging materials are treated as high-risk items and require secure storage, controlled issuance, and reconciliation.

Distribution readiness

Finished goods warehouses support dispatch with checks on batch release status, packaging integrity, shipment documentation, and transport qualification (especially for cold chain). Recall readiness depends on accurate distribution records and batch traceability.

Common inspection gaps include mixed-status storage, weak temperature control, poor pest control, missing location discipline, and incomplete traceability. A robust warehouse system demonstrates disciplined segregation, monitoring, documentation, and continuous compliance with GMP/GDP.