UNDERSTANDING RAPID MIXER GRANULATOR IN PHARMA

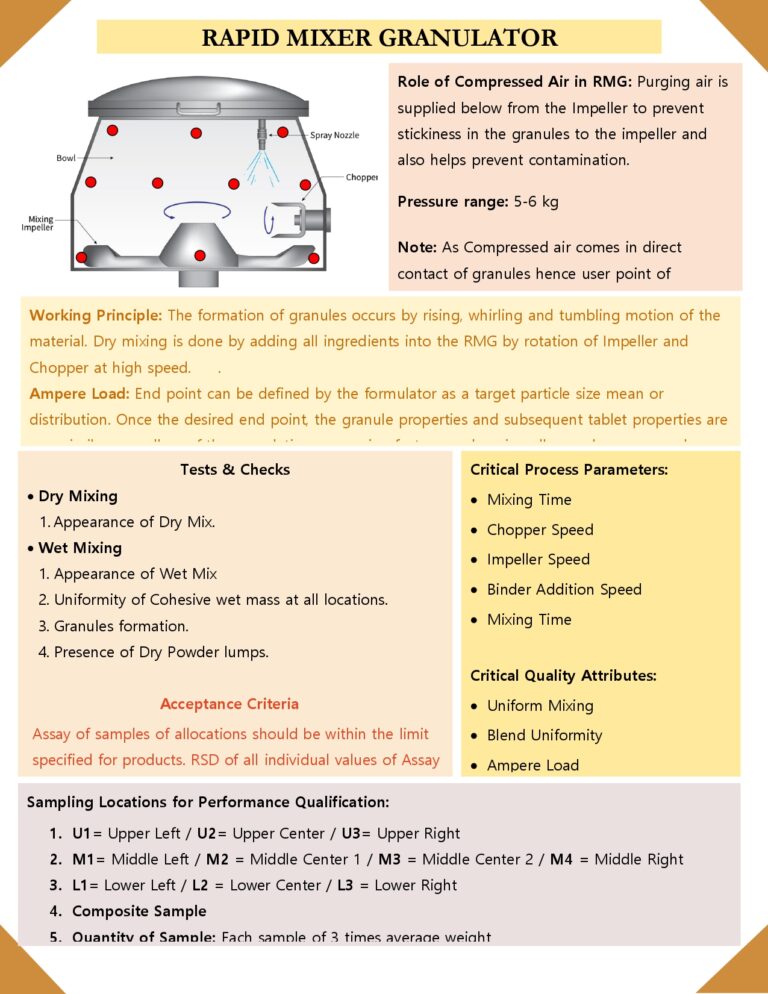

A Rapid Mixer Granulator (RMG) is a high-shear granulation machine used in pharma to convert powder blends into dense, uniform granules that flow well and compress consistently into tablets. It typically has two main agitators inside a closed bowl: an…