Daily balance verification in pharma is the routine, documented checking of analytical balances each day they’re used to ensure they are accurate and fit for use in GMP testing. It’s a pre-use fitness check, not a full calibration.

Here’s a crisp, SOP-style explanation you can directly adapt.

1. Purpose

- To confirm that each analytical balance used for GMP/testing is:

- Functioning correctly

- Within predefined accuracy/precision limits

- Safe to use for weighing of reagents, standards, and samples

If daily verification fails → do not use the balance for any GMP work until investigated and found acceptable.

2. What Needs to Be Defined in SOP

Your “Daily Balance Verification” SOP should clearly define:

- Scope

- All analytical balances used in:

- QC lab

- Production (dispensing, weighing rooms)

- R&D (if data used for CGMP decisions)

- All analytical balances used in:

- Frequency

- At the beginning of each day of use

- Additionally:

- After relocation

- After power failure

- If the balance shows abnormal behavior (drift, error messages, or suspected damage)

- Responsibility

- Trained analysts / production operators

- Review by QA/QC supervisor (for trend and OOS actions)

3. Pre-Checks Before Verification

Before starting daily checks:

- Ensure balance is level (spirit bubble centered).

- Draft shield doors closed (if applicable).

- Balance is clean (no spills or powder).

- Warm-up time completed (as per manufacturer).

- No strong air draft, vibration, or direct sunlight.

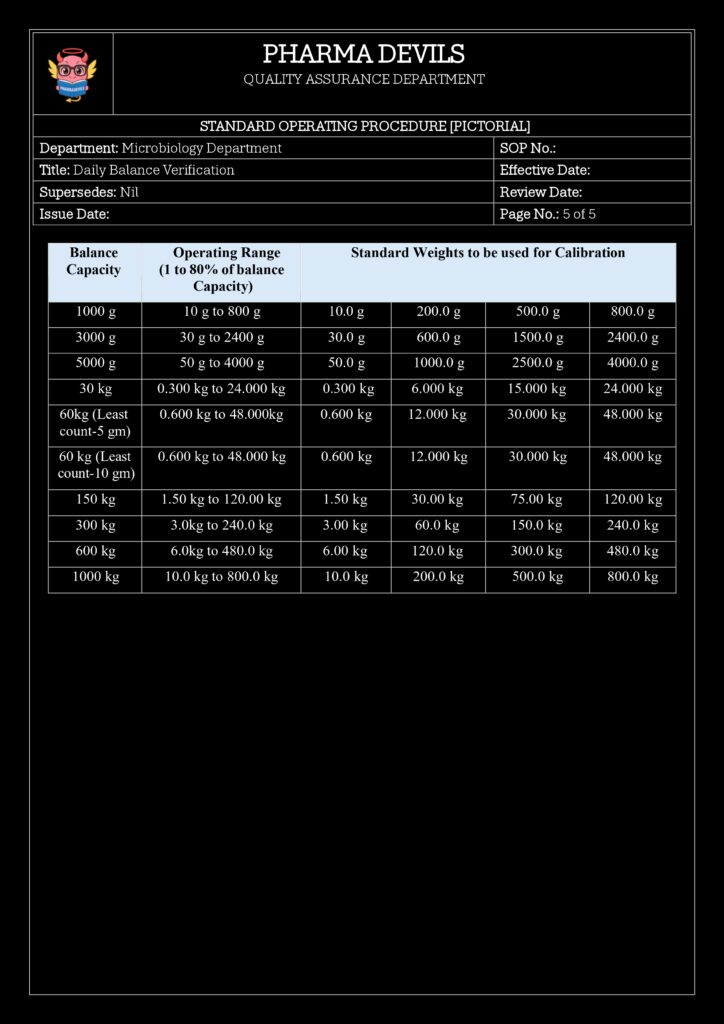

4. Standard Weights and Their Control

Use certified reference weights with known values and tolerances:

- Typically Class E2 / F1 OIML or equivalent, depending on balance readability.

- Maintain:

- Weight ID (e.g., W-10g-01)

- Nominal value (e.g., 10 g)

- Certificate number, traceability to national/international standards

- Calibration due date

Weights must be:

- Stored in clean, closed boxes.

- Handled with tweezers or gloves to avoid contamination.

- Kept near the balance (same environment) for temperature equilibrium.

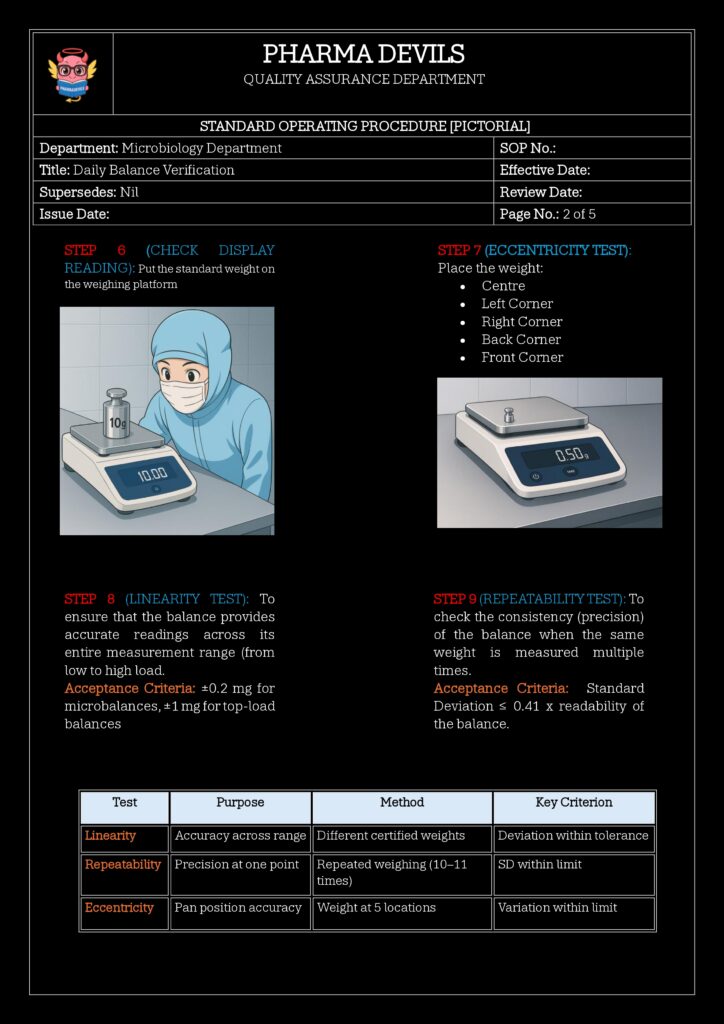

5. Typical Daily Verification Procedure

You can express this as a step-wise checklist in the SOP/poster:

- Power On & Warm-Up

- Switch on balance (if not 24×7).

- Allow recommended warm-up period.

- Zero / Tare Check

- With empty pan, press ZERO.

- Confirm reading is 0.0000 g (or 0.00000 g depending on resolution).

- Internal Adjustment (If Available)

- Run internal calibration/adjustment as per manufacturer’s instructions.

- Document performed, if your SOP requires.

- Place Certified Weight(s)

Recommended approach:- Use at least two weights:

- One near the lower or mid-range (e.g., 10 g)

- One near the upper range (e.g., 100 g) of routine use

- Record displayed value vs. nominal value.

- Use at least two weights:

- Calculate Error

- Error = |Displayed value – Nominal value|

- Check against predefined allowable tolerance (e.g., ±0.2 mg for 10 g, etc., based on risk and balance capability).

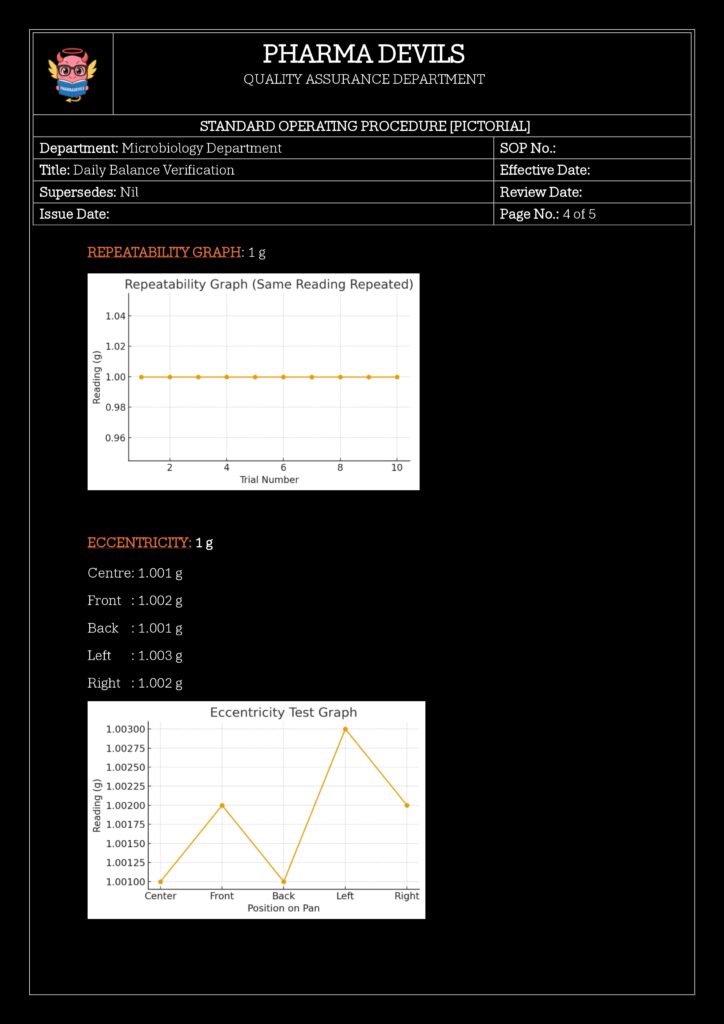

- Repeatability Check (Optional but Good Practice)

- Weigh the same weight 3–5 times, removing and replacing it.

- Calculate standard deviation (or range).

- Compare with defined acceptance criteria (e.g., σ ≤ 0.15 mg).

- Return to Zero

- Remove weight and ensure balance returns to 0.0000.

- If not, investigate and repeat as needed.

- Documentation

- Record in a log:

- Date & time

- Balance ID

- Weight ID(s)

- Nominal vs. observed values

- Calculated error

- Pass/Fail

- Analyst initials/signature

- Record in a log:

6. Acceptance Criteria (Example)

These must be defined in your validation/QRM, but common pattern:

- Accuracy:

- Error for 10 g weight must be within ±0.002 g

- Error for 100 g weight within ±0.02 g

(Adjust for your balance readability and process criticality.)

- Repeatability:

- Standard deviation ≤ 0.0002 g for 10 g weight over 5 measurements

- Or %RSD within predetermined limits

You can link these to your calibration certificate and balance qualification report.

7. What if the Balance Fails?

If any verification step fails:

- Immediately label the balance “OUT OF SERVICE”.

- Stop using it for any GMP weighing.

- Notify supervisor/QA.

- Initiate investigation:

- Check if wrong weight used, dirty pan, drafts, etc.

- Re-verify after corrective actions.

- Evaluate impact on previously weighed materials:

- Trace back to last successful verification.

- Assess impact on results and product quality.

- Document in deviation/OOS and decide on re-testing or re-weighing if possible.

8. Link to Calibration and Qualification

Daily verification is complementary to:

- Periodic external calibration (e.g., 6–12 months).

- Equipment qualification (IQ/OQ/PQ).

- Preventive maintenance.

Regulators expect:

- Documented evidence that equipment is fit for intended use at the time of use.

- Daily checks + calibration + qualification together provide that assurance.