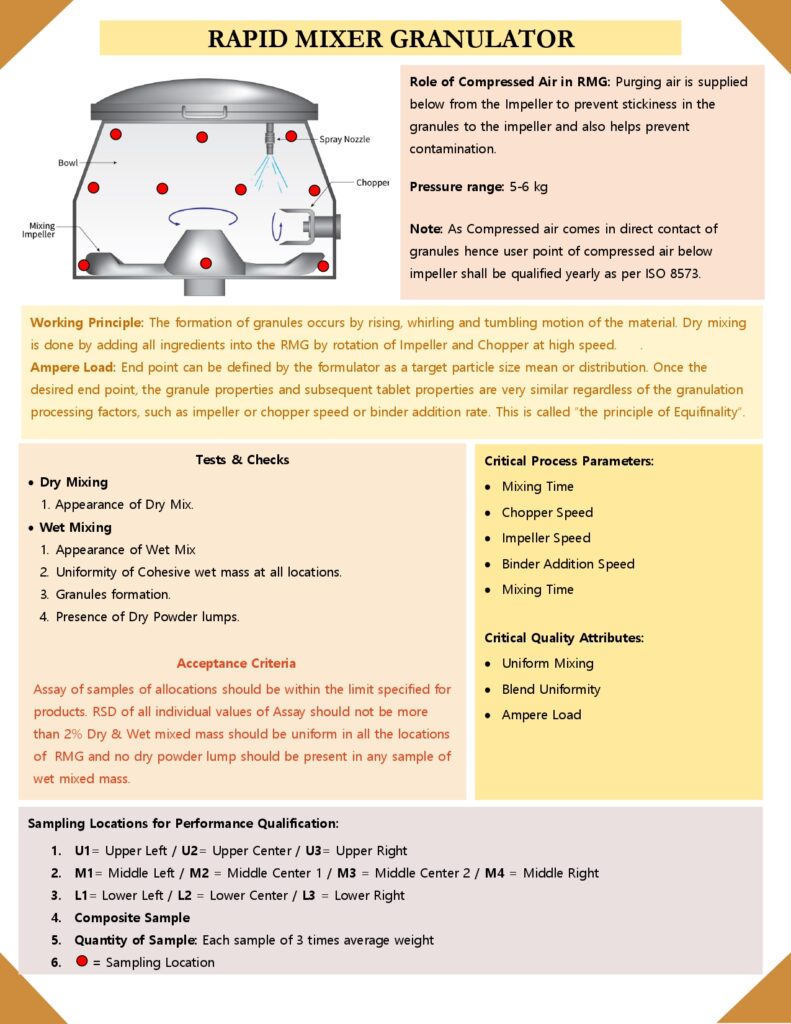

A Rapid Mixer Granulator (RMG) is a high-shear granulation machine used in pharma to convert powder blends into dense, uniform granules that flow well and compress consistently into tablets. It typically has two main agitators inside a closed bowl: an impeller (main mixing blade) and a chopper (high-speed cutter). The process starts with dry mixing, where API and excipients are blended to achieve content uniformity. Next is wet granulation, where a binder solution (or sometimes purified water) is added in a controlled way—by spray or pour—while the impeller distributes liquid and the chopper breaks wet lumps. This creates a balance between nucleation (initial granule formation), growth (granules enlarge by layering/agglomeration), and breakage (oversized lumps are cut down), leading to a targeted granule size distribution.

Key process variables include impeller speed, chopper speed, binder addition rate, total binder quantity, granulation time, and bowl load. These directly influence granule density, size, porosity, and moisture, which later affect drying efficiency, lubrication behavior, tablet hardness, friability, and dissolution. End-point control is critical and may be based on power/torque rise, time, or in advanced systems, PAT tools (e.g., in-line torque trending).

RMG benefits include fast processing, good uniformity, strong granules, reduced dust, and suitability for potent drugs when integrated with containment. Common issues are over-wetting (large sticky lumps), under-wetting (weak granules, fines), over-granulation (too dense, slow dissolution), or poor binder distribution. After granulation, the wet mass is discharged to a dryer (often fluid bed dryer) and then milled/sieved to meet final granule specifications.