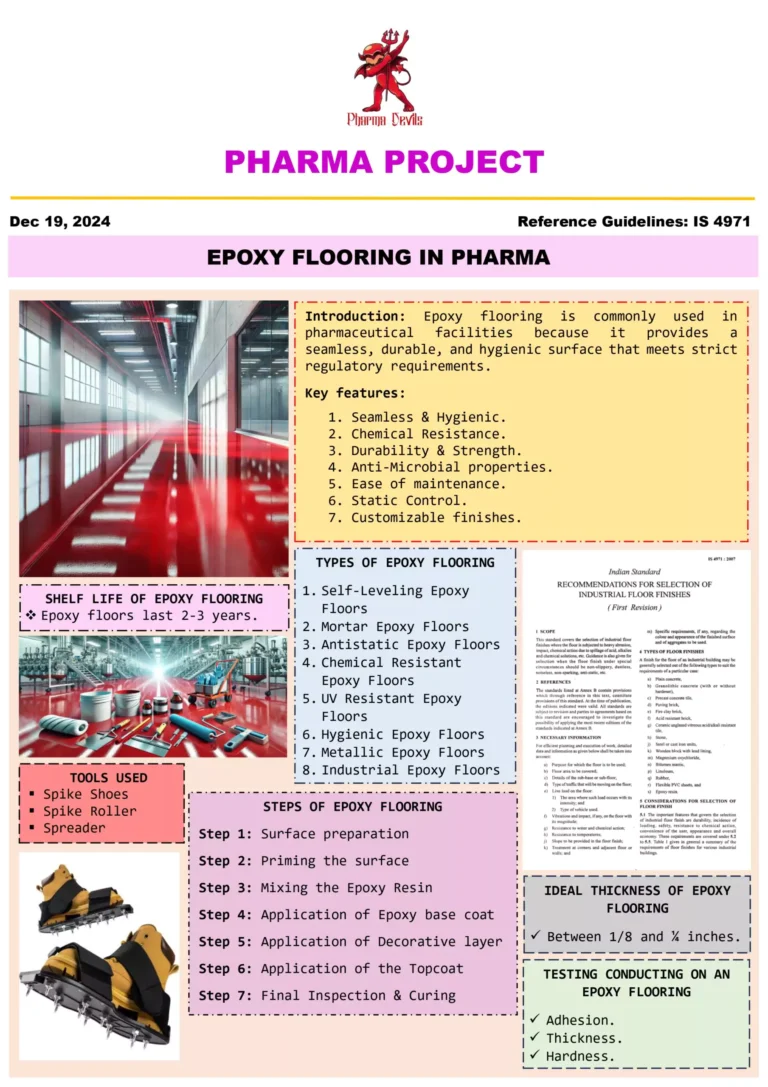

EPOXY FLOORING IN PHARMA

Epoxy flooring in pharma is a seamless, non-porous resin floor system used in manufacturing, packaging, QC labs, and warehouses to support GMP cleanliness, durability, and contamination control. Its main value is that it creates a surface that is easy to…

![RISK BASED INSPECTION [SCHEDULE M-POINT (39.21)]](https://pharmadevils.com/wp-content/uploads/2024/11/SCHEDULE-M-39.21-768x1087.jpg)

![RISK BASED INSPECTION [WHO TRS 986-POINT (39.17)]](https://pharmadevils.com/wp-content/uploads/2024/11/WHO-TRS-986-39.17-768x1087.jpg)

![RISK BASED INSPECTION [SCHEDULE M-POINT (34.14)]](https://pharmadevils.com/wp-content/uploads/2024/11/SCHEDULE-M-39.14-768x1087.jpg)